Our customer

The Electrolux group is a leading global household and kitchen appliances manufacturer. Established in 1919 in Sweden, the group provides thoughtfully designed innovations. In 1925, the company started its activities on the German market and currently has a staff of 2,000 in Germany, with 1,300 employees working at the plant Rothenburg ob der Tauber.

Customer benefits

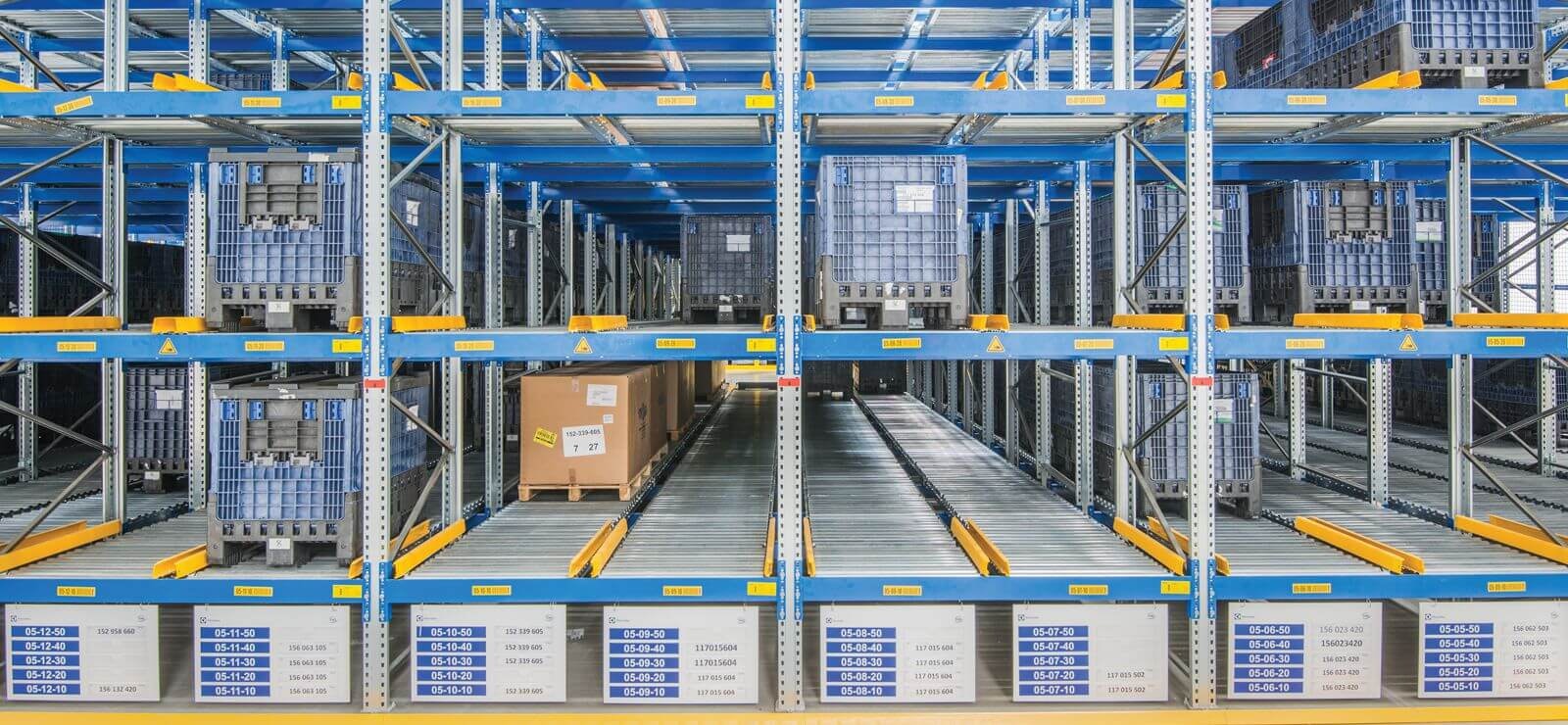

- Occupancy costs can be reduced due to the small amount of space required

- Safety First: High level of safety when operating the racking installation, very low risk of accidents

- Shorter travel routes – lower in-house transport costs

- No disruptions in the manufacturing process, no production downtimes