Our claim to quality is our answer to the question of sustainability.

BITO products are sustainable because they have been designed for a long service life and manufactured to the highest quality standards. Already when selecting the raw materials and supplies used for manufacturing our products, we pay attention to quality

Sustainable and durable storage solutions

Once assembled, BITO shelving and racking operate reliably during their entire service life. Regular racking inspections and maintenance also add to safety and durability. Choosing the right storage system will result in significant time and cost savings. Compact storage and a clear product presentation help reduce order throughput times and coordinate logistical processes. This avoids downtime, increases warehouse productivity, reduces storage costs and energy consumption and increases efficiency.

BITO shelving and racking is made from quality steel and comes with an electrostatically applied powder coated finish instead of conventional liquid paint which needs an evaporating solvent. Powder-coated workpieces are extremely impact-resistant, weatherproof and durable. We only use colour pigments that are ecologically safe and release a very low amount of volatile organic compounds during the coating process. Typically, powder coatings are cured at temperatures of 140 - 200°C. We use advanced low bake thermosetting powder that cross-links at temperatures of less than 140°C to minimise emissions and energy consumption during production.

Sustainable bins & containers

During their long service life, BITO bins and containers will each save tons of cardboard packaging.

BITO Bins and containers are – regardless of the variant – the ideal, strong and durable alternative to disposable cardboard boxes.

BITO bins and containers are made of quality plastic and are therefore extremely hardwearing and durable. They can be reused hundreds of times. Reusable containers are a particularly sustainable storage and transport solution, because they replace hundreds of disposable cartons and help to avoid a lot of packaging waste.

BITO plastic bins and containers that are intended for food contact are made from food safe material in compliance with EU law. Supplied with drop-on lid and metal snap locks, BITO MB containers have been approved for transporting hazardous goods; they also protect the environment by preventing leakage.

Users are becoming increasingly aware of the need for sustainability. To save on packaging material, durable multi-trip containers have always been in demand for storage and order picking applications as well as for transport and in production environments, such as in Kanban workflows. Today, more and more customers are placing greater value on sustainability in these areas as well.

Energy-efficient production and ecological alternatives to goods made from virgin plastics

As ecologically minded supplier, it is important for BITO to offer alternative products that are not made from virgin plastics, Every ton of polypropylene not produced saves 1.7to CO₂.

Well organised recycling processes

Using recycled materials or blends such as sunflower compound will reduce the tonnage of very energy-intensive plastic granules (PP) and reduce our carbon emissions.

For many years now, BITO has been providing well organized recycling services for plastic bins and containers. For customers who place particular emphasis on sustainability, plastic waste, rejects, returned bins and containers, etc. are ground up in a company-owned facility and new containers or accessories are produced from this recycled material.

Due to increasing demand, BITO has been manufacturing the most popular container sizes of their MB reusable container series from regranulated certified "post-consumer plastic", i.e. recycled plastics from household waste since the end of 2019.

This means that the MB ECO series is not only about "recycling", but also about "upcycling". In this way, a disposable, single-use product is transformed into a long-lasting, high-quality and environmentally friendly reusable container.

The environmental impact is threefold: household waste is not incinerated (reduces pollutants in the air), the material is not expensively produced from petroleum (saves approx. 950 kg CO₂ per ton of PP) and, like all BITO reusable containers, the MB ECO replaces disposable transport packaging many times over.

Bin inlays, inserts & dividers

Application-specific divider systems and customised, reusable bin inlays

BITO continuously works on developing new features for their bins and containers in order to help reduce packaging waste with well designed system solutions. Subdivision systems, such as front-to-back and cross dividers, push-fit inlays and insert boxes, make sure that goods are stored in a secure and well-protected way in precisely fitting compartments to eliminate the need for additional disposable packaging and protective filling materials. Reusable, customised inlays, compartments and interior fittings developed by BITO as a special solution adapted to customer requirements are an environmentally friendly alternative to disposable packaging. They protect products in the best possible way during storage and transport and help to save space.

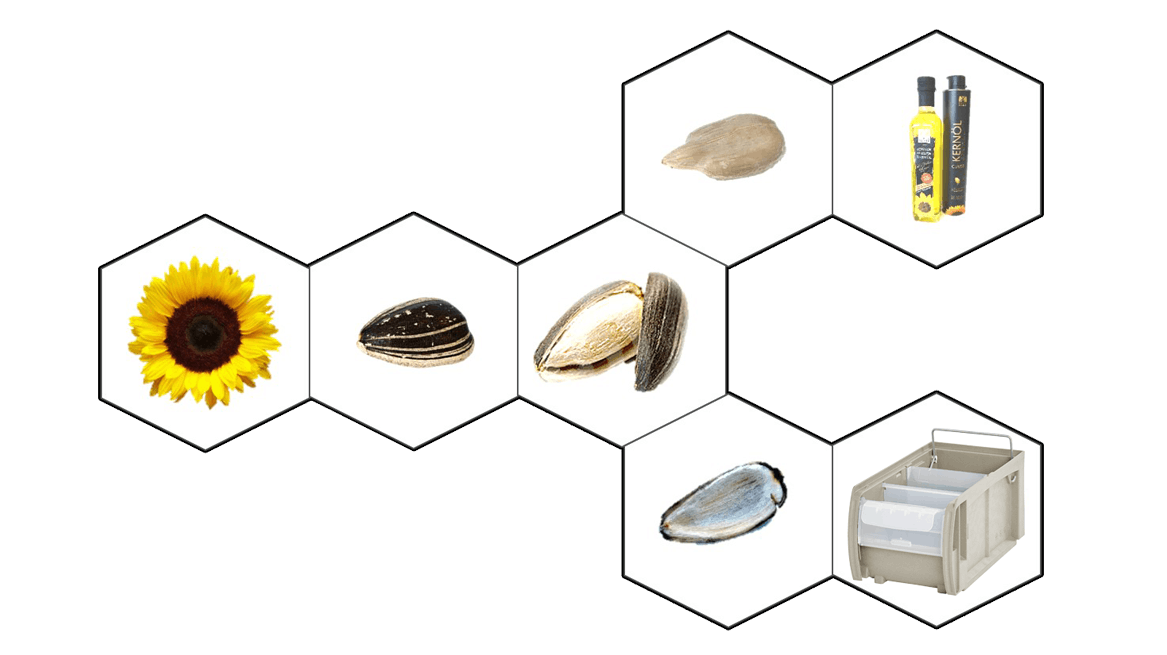

Bins made from a PP and sunflower seed shell compound

BITO Sunflower-Compound

A special alternative to conventional polypropylene (PP) is the environmentally friendly material Sunflower Compound (SFC), which is used to manufacture the BITO Sunflower Compound SFC containers for C-items. With this small parts container series made from sunflower seed shells, BITO-Lagertechnik has set a milestone towards sustainability in the production of plastic bins and containers. Since 2018, BITO has been producing this container series by adding this natural material to conventional polypropylene.

Processing waste products

No foods are needed to produce sunflower seed shells, nor is any additional acreage required, as the shells are a by-product of sunflower seed production. Instead, a lot of energy can be saved during production and the CO₂ footprint can be further reduced by using this material.

How does this work?

Until now, the shells were only a waste product of the food industry, while sunflower seeds are used to produce oil, for example, or used directly as food. A young company came up with the idea of using this natural raw material as a filler and reinforcing material in plastics, since this by-product of sunflower seed production is suitable as a fiber additive for the production of high-quality natural fiber plastics. To obtain the environmentally friendly mixture, the shells are ground and then compounded with polypropylene, i.e. bonded. The plastic composite has excellent processing properties and is characterized by a high degree of rigidity and impact strength. This material is suited for producing high quality containers.

No foods are needed to produce sunflower seed shells, nor is any additional acreage required, as the shells are a by-product of sunflower seed production. Instead, a lot of energy can be saved during production and the CO₂ footprint can be further reduced by using this material. The production of this composite generates fewer greenhouse gases than the production of conventional "pure" plastic. In addition, lower temperatures are required to process the material, thus reducing the amount of energy needed.

Future success and innovations are primarily the result of a strong partnership with our customers.

"Our products are the door openers, but the tangible difference for customers is our ability to realise complex projects around the world with absolute reliability. This is what we focus on in our Project Business Division. Future success and innovations are primarily the result of a strong partnership with our customers and we will continue to build on these partnerships."