Schülke & Mayr

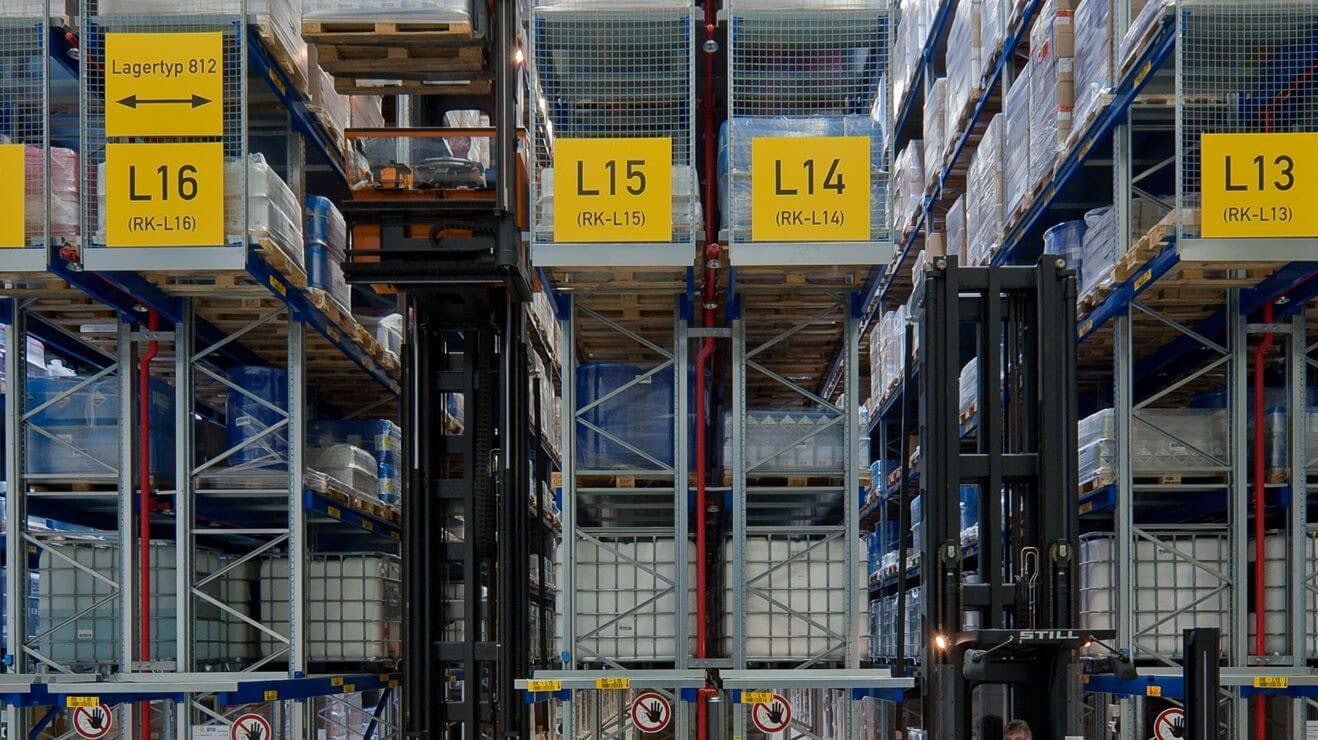

Safe storage of hazardous goods in a BITO combination of pallet racking and a mezzanine floor with boltless shelving

Our customer

Since Schülke & Mayr was founded in 1889, the chemical pharmaceutical company has been a leading specialist in hygiene, infection prevention and chemical technical preservation. In 1996, they joined the French Air Liquide group. Today, Schülke & Mayr employs more than 600 people with 440 employees working in Germany and 90 in subsidiaries abroad.

Initial situation and customer requirements

- Establishment of a new logistics centre to accommodate different load carrier types such as IBCs, Euro pallets and non-palletised unit loads.

- Observe fire safety regulations as well as environmental laws and directives imposed by public authorities.

- Find a versatile storage solution that adapts to changing requirements.

Some impressions of our customer solution

Project brief

The BITO Solution

Compact storage in 4 sectors

» The integrated logistics centre consists of 4 sectors (compartments) providing a total of 18,500 pallet positions.

Pick & buffer areas

» Another order picking warehouse and interim storage facility was equipped with a pallet racking system providing 650 pallet positions.

Mezzanine floor

» For additional storage and work space, a mezzanine floor was fitted on top of BITO shelving

Narrow aisle storage

» High-density storage system with narrow aisles and an inductive track guidance system.

Push-back pallet racking for collective deliveries

» The push-back pallet racking block is another important part of the racking package. It is used for the interim storage of collective deliveries to be shipped to foreign markets.

On-site application and key features of our storage solution

- The main warehouse comprises four sectors for product supply and intermediate storage.

- In case of fire, sprinklers are activated and each sector can be closed off hermetically with automatic fire-resistant doors.

- In compliance with fire prevention regulations, racking in sprinkler-protected areas is additionally fitted with in-rack heat shield steel panels.

- All roller conveyor lanes feature brake rollers fitted to every pallet position.

- The space on the mezzanine floor is used for storing advertising material on BITO shelving.

Customer benefits

In what way has the BITO solution helped our customer to realise their full potential?

- Storage and order picking have been merged into one logistics centre.

- Maximum product availability while complying with all relevant fire prevention and environmental protection regulations for maximum safety.

- Shorter travel routes

- Brake rollers in push-back racking lanes avoid damage to pallets and products.

„With up to 250,000 pallets to be handled each year, and especially with the type of materials that we handle, it is important that the logistics facilities not only work smoothly, but that sufficient measures are taken to ensure safety in a fast-paced environment. If you want to implement a project of this size in compliance with all regulations and on schedule, you need a reliable partner who is able to take a flexible approach.“