The BITO Solution

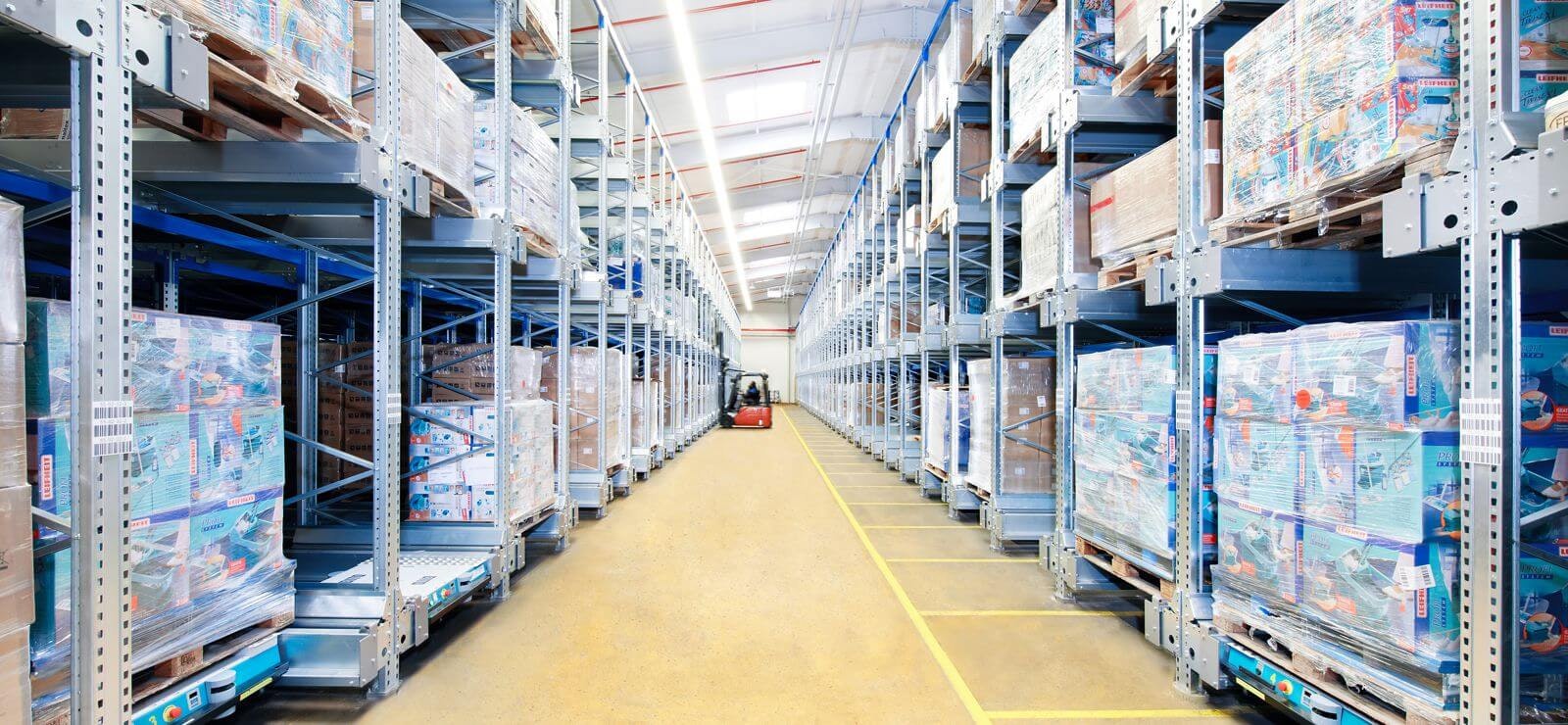

- More pallet positions

» With this shuttle-assisted BITO PROmotion facility, Leifheit was able to increase their storage capacity by some 10,000 pallet positions.

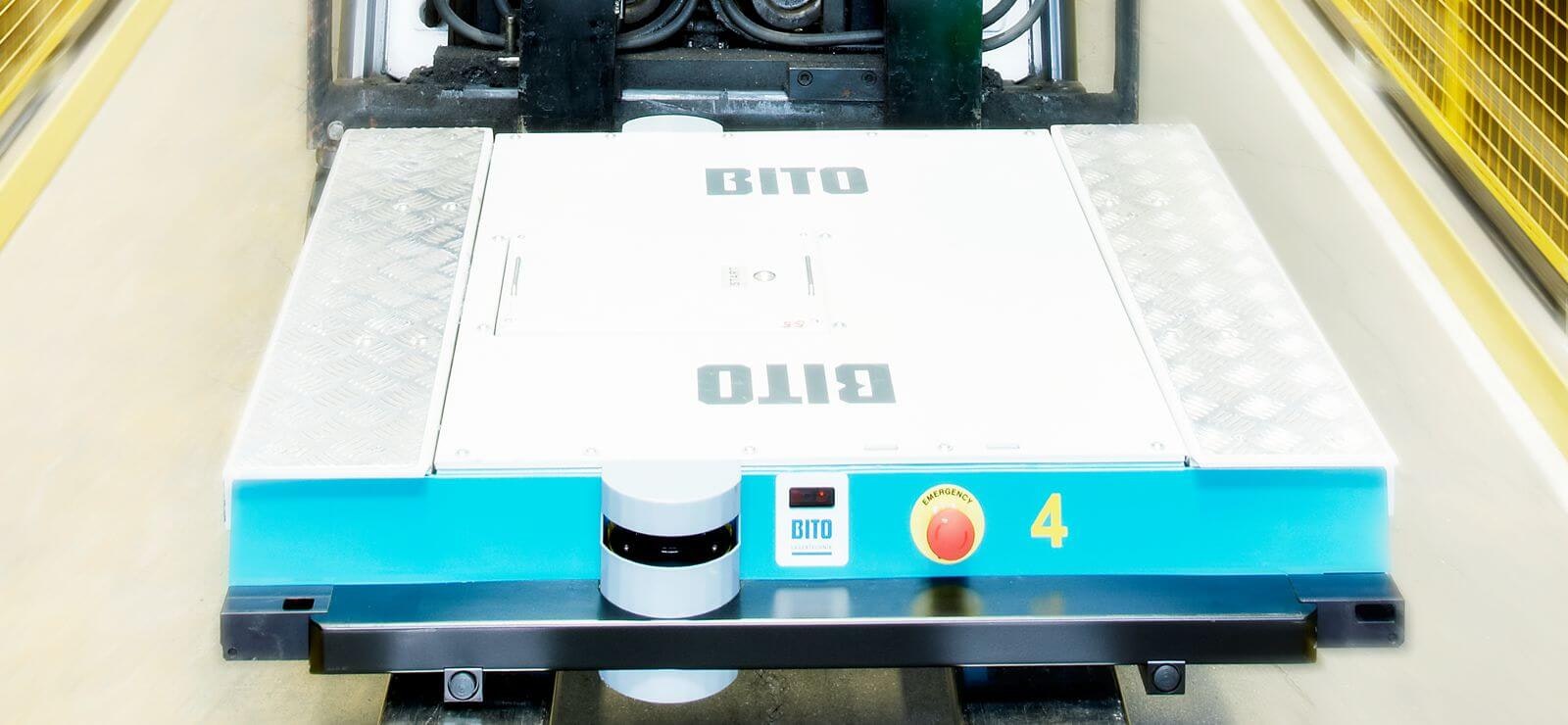

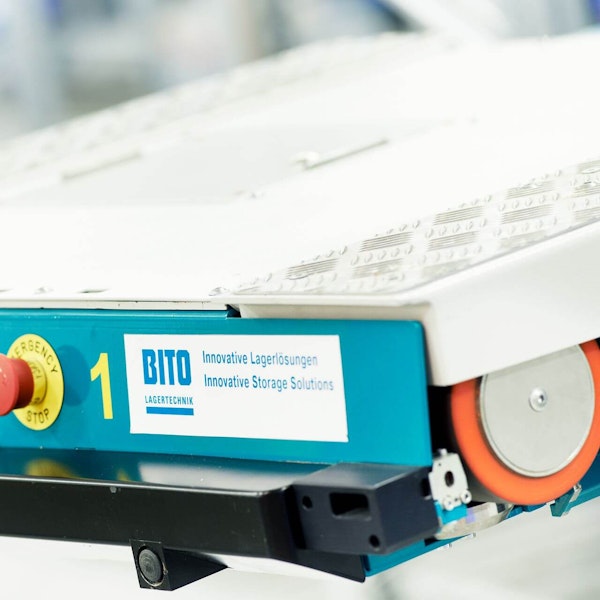

- Remote-controlled pallet handling

» 6 battery-operated and remote-controlled shuttle vehicles are used to move pallets into and out of racking lanes.

- Long lanes

» With a depth of 10 to 16 metres, the lanes of this facility offer compact pallet storage.

Customer benefits

- As opposed to block storage, the BITO solution ensures optimum use of floor surface and warehouse height, thereby increasing the total amount of pallet positions.

- Each lane can be directly accessed.

- Compared to push-back racking, BITO PROmotion has the decisive advantage that longer lanes can be realised.

- In our case, the number of pallet positions increased from 43,000 to 53,000.