Meradog

BITO PROflow pallet live storage increases throughput in a pet food processing plant

Our customer

» Pet well-being is the goal and commitment of Mera Tiernahrung GmbH from Kevelaer in the Lower Rhine region. The family-run company has more than 60 years of experience in the production of premium pet food for dogs and cats. A strict quality assurance system is being followed in the entire state-of-the-art production process which has been audited and certified by independent institutes.

Initial situation and customer requirements

- A high turnover of goods must be guaranteed.

- The new storage system must be maintenance-free.

- Space is limited.

- Strict hygienic standards must be observed.

- A racking system is needed to buffer pallets with dog food until the time the pallets are picked for delivery.

- Goods must be stored in FIFO order to adhere to use-by dates.

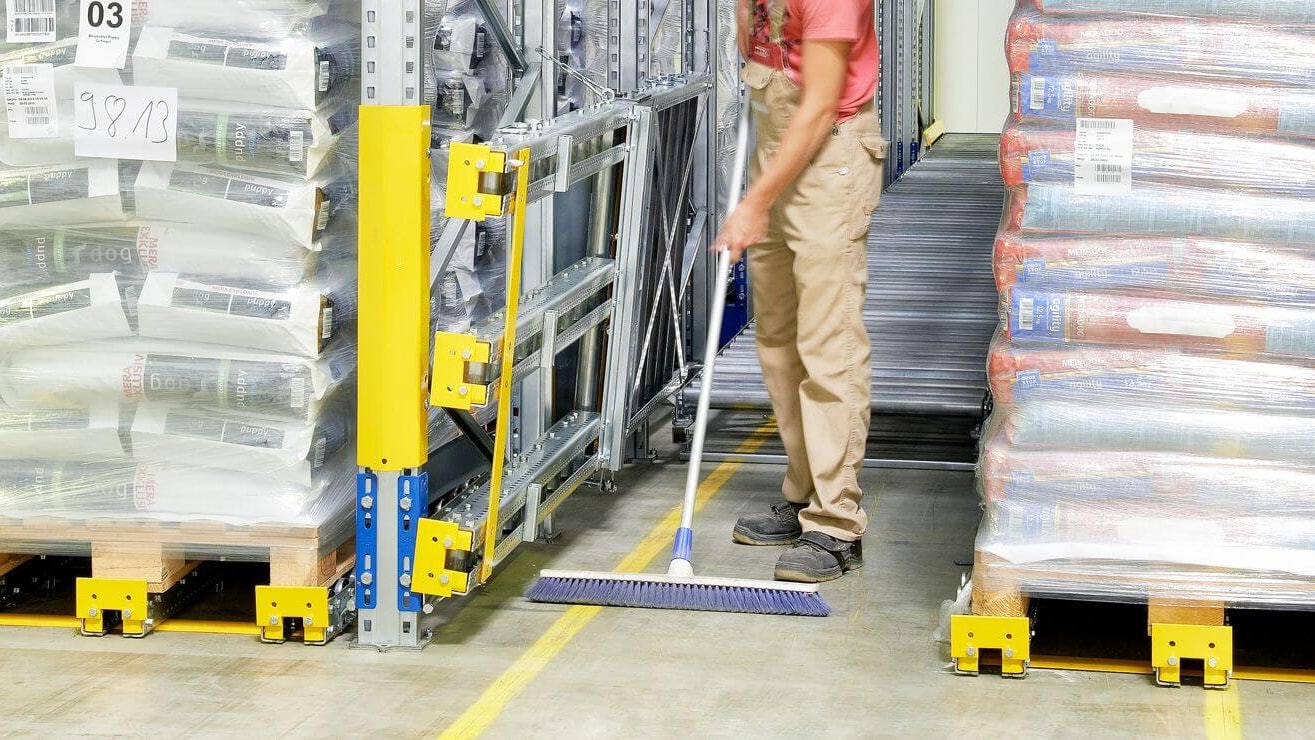

Some impressions of our customer solution

Project brief

The BITO Solution

Product buffer

» BITO PROflow pallet live storage is ideal for FIFO product buffering.

Optimum operational reliability

» The BITO FlowStop mechanism is practically maintenance-free and prevents downtimes.

On-site application and key features of our storage solution

- Goods are buffered in a BITO PROflow pallet racking facility.

- Finished products are stored in cartons and bags on Euro pallets.

- FIFO stock rotation is guaranteed.

- Goods are picked order-related right from the live storage facility.

Customer benefits

In what way has the BITO solution helped our customer to realise their full potential?

- Space-saving high-density storage in BITO PROflow pallet live racking.

- The increase in storage capacity on the same floor area speeds up order throughput.

- FIFO storage ensures easy monitoring of best-before dates.

- Hinged roller conveyor lanes enable convenient floor cleaning, which is essential for food safety and hygiene.