BITO Solutions for cold storage and safe, temperature-controlled shipping

Chilled and frozen foods need to be kept within a specified temperature range during storage and transportation. BITO Solutions ensure optimum space utilisation, maximum cost savings and real-time monitoring of temperature and other parameters.

Shelving and racking for cold stores

As enclosed storage space in cold stores is particularly expensive due to electricity consumption, the available space must be used particularly efficiently. This means that a storage system must make maximum use of the floor space and the warehouse cube. Storage systems that are suited for this purpose are BITO mobile pallet racking, pallet live storage racking and shuttle-serviced pallet racking. PROmobile pallet racking from BITO can increase your storage capacity by up to 180 percent on the same floor space, thus avoiding the need for potentially expensive new warehouse buildings. Compact storage saves up to 50 percent of the previously required storage space, which can now be used for other (value-adding) processes. Especially in freezer warehouses, efficient and space-saving storage results in considerable savings in energy costs. PROflow pallet live storage racking from BITO enables high-density FIFO storage. As there is only one loading and one picking aisle, internal transport routes are reduced by an impressive 40 percent. Moreover, up to 60 percent more storage space is gained in comparison to conventional pallet racking. This increase in efficiency not only helps to reduce energy consumption for in-house transport, but also significantly lowers the overall energy requirement in your warehouse. In contrast to a pallet live storage system, storage levels in a PROmotion shuttle-serviced warehouse do not require any level incline. This means that no space is lost in height which again increases storage density. The entire height of your premises can be optimally utilised. By using several shuttle carriers, particularly high handling rates can be achieved. In shuttle-serviced warehouses, products can also be stored in FIFO order, which means that best-before dates can be adhered to. Of course, racking in cold storage areas must be especially protected against adverse environmental conditions. This is why stainless steel shelving and racking come with an additional protective surface coating. Powder coating with RAL colours and galvanising are particularly suitable for this purpose.

MB containers as cool boxes

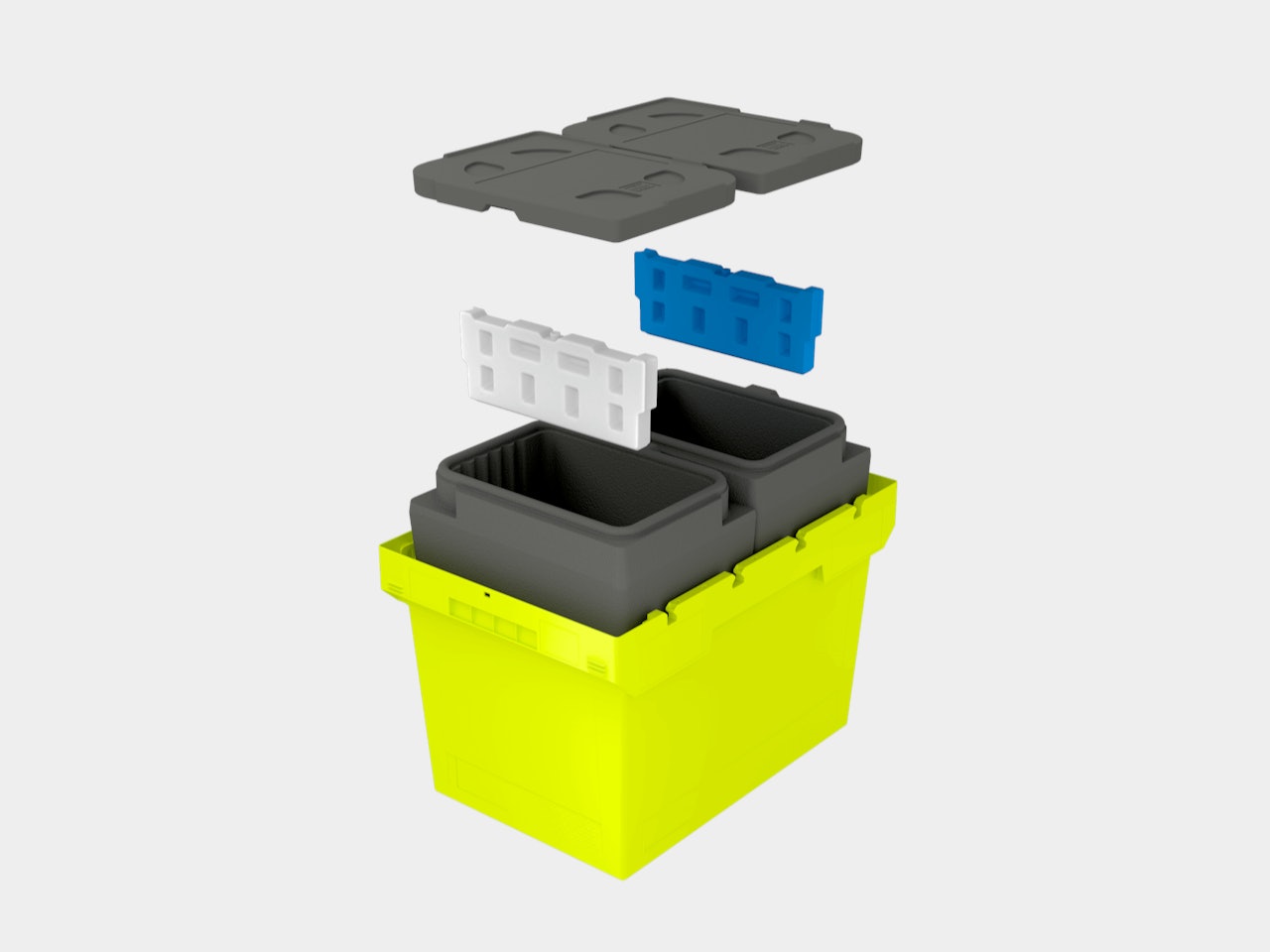

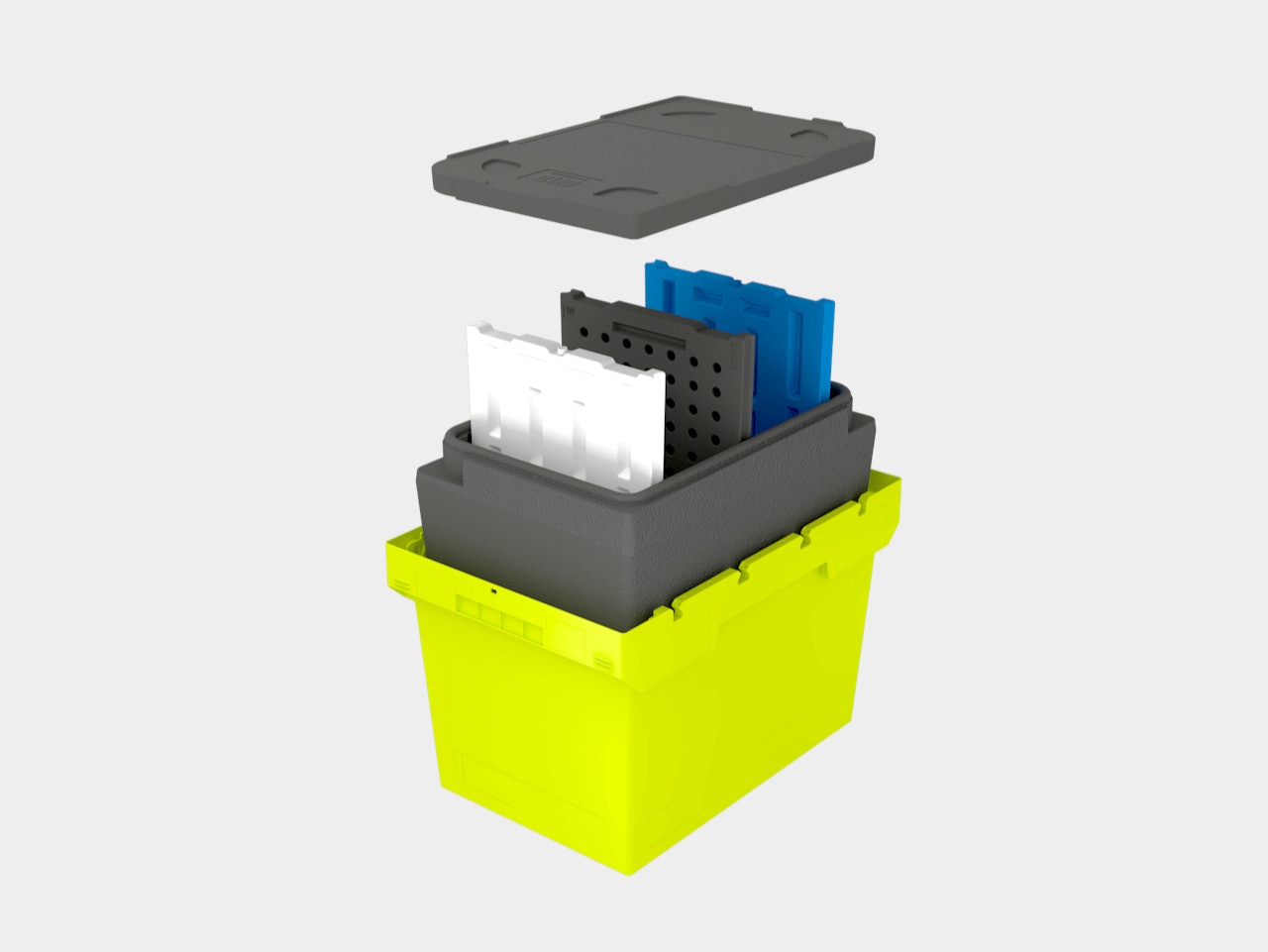

Food retail and e-commerce can rely on a perfect, passively cooled container system from BITO - the MB Food & Delivery tote which can be ordered in several sizes and complete with modular insulating inserts, cold packs and dividers. With their innovative design, MB Food & Delivery containers can accommodate a wide variety of foods in a space-saving way, which is why they are particularly suited for last mile deliveries. The flexibility of the system is underlined by various individual configuration options. The inserts are made from expandable polypropylene (EPP) and are available in various sizes to enable the subdivision into different cooling & temperature ranges. Full height or half height cold packs help to maintain the right cooling temperature. In order to keep temperatures within the optimum range in refrigerated food transport vehicles and in cold stores, the MB Food & Delivery Box is also available with vented sides. This improves cooling conditions and also reduces the tare weight of the container, thus minimising the strain on staff. Specifically designed inserts ensure that nothing can slip, tip over or leak. The possibility of nesting empty containers to save space adds to the efficiency and adaptability of this premium container system. In summary, the MB Food & Delivery tote represents a perfect symbiosis of innovation, functionality and optimum protection for perishable foods.

Transport solutions for the cold storage sector

Extremely low temperatures in cold storage facilities are a considerable challenge for the technical equipment, storage and retrieval machines, conveyor technology and industrial trucks. Forklift trucks, for example, must be operated with cold storage hydraulic oil and fitted with special seals.

BITO Solutions for storing and transporting frozen foods in compliance with laws and regulations

Companies in the food sector are required to implement, maintain and continuously adapt an HACCP/self-monitoring system. EU Regulation No. 852/2004 also indirectly stipulates that the cold chain must be maintained at all times.

Efficient space utilisation in cold stores has top priority

Cold stores represent a particular challenge. The efficient utilisation of the expensive storage space is particularly important. Each cubic metre of the enclosed space of a cold storage facility is expensive, both in terms of construction and operation. Due to the high electricity consumption, cold stores need to be well planned and built. Modern solutions utilise photovoltaics with energy accumulators. Innovative solutions are also in high demand for efficiently transporting refrigerated goods, particularly in e-commerce. Vehicles with multiple compartments are playing an increasingly important role for last mile deliveries. Food retail and e-commerce can rely on a perfect, passively cooled container system from BITO: The MB Food & Delivery Box which can be ordered in several sizes and complete with modular insulating inserts, cold packs and dividers.

What are the benefits of a cold storage solution from BITO?

We supply quality shelving and racking manufactured in our own plant for deep-freeze applications

At BITO, we also manufacture shelving and racking for deep-freeze environments in our own state-of-the-art plant in Meisenheim. We only use quality steel. The surfaces are galvanised or epoxy-coated to protect the components against corrosion and damage.

Passive cool boxes for the food & delivery sector

The BITO Food & Delivery Box has been especially designed for the food industry.

The box is part of a cleverly designed system with optional features that is perfectly tailored to the requirements of grocery retail and the e-food sector. Specifically designed dividers ensure that nothing can slip, tip over or leak. Fitted with insulation inserts that are available in two modular sizes, the box can be subdivided into two temperature zones. Upon request, the box can be supplied with bag holder rails. Cold packs made of phase-change materials (PCM) are used for cooling and can also be used for subdividing containers. Various PCM cold packs are available to suit different cooling ranges. In addition to boxes with solid sides, our range also offers boxes with ventilated sides, which are particularly suitable for use in temperature-controlled vehicles or cold stores.

Real-time monitoring of temperature and other parameters

With the SmartHub (SmartLock), beacons and cloud connectivity software, it is easy to monitor temperature and other parameters such as geodata in real time, both from the MB Food & Delivery Box and from cold storage areas. The system allows you for example to document compliance with cold chain requirements. The SmartLock functionality shows whether a cool box has been accessed or tampered with.

Optimal solutions for cold storage warehousing

BITO also supplies comprehensive modular solutions for your cold store. These include shuttle-serviced pallet racking, live storage systems for fast-moving items and mobile racking – all offering a very high degree of space utilisation. We also supply real-time temperature monitoring solutions, lift trucks for cold stores and other technical equipment.

BITO Storage solutions grow with your business

BITO provides storage solutions for production environments that can be easily scaled and flexibly adapted given the available space. The handling capacity of shuttle-serviced pallet racking can easily be increased by using additional shuttle vehicles. Adjustments can be made by reconfiguring the racking layout or by extending the entire system.

Together we will find the best solution

At BITO, we value effective communication and comprehensive advice. Whether you are planning and building a fully equipped logistics centre or require an integrated systems solution for your cold store, we are your reliable partner. We are thoroughly convinced that the best solutions are found through intensive dialogue with our customers.

BITO Warranty

We provide a comprehensive BITO warranty for all products and services. As a renowned manufacturer of material handling and storage equipment, we are fully committed to delivering premium products and services. The BITO brand name is synonymous with outstanding quality and reliability.

Broad range of accessories

We offer a wide range of components and accessories for cold storage logistics in our BITO Online Shop. Examples include roller conveyor segments, roller tracks, roller rails and roller rail guards, roller lanes with full-width rollers, push-back stops, pallet support bars, lithium batteries for PROmotion shuttle carriers and chargers, containers with drop-on lids, cold packs, insulating inserts (full size or half size) and cross dividers.