Ideal if...

- You want to make maximum use of your storage area across multiple levels.

- You want to make the most efficient use possible of the surface area and height of your storage space.

- You need a particularly stable solution for storing heavy loads. A mezzanine floor's capacity can even exceed 1000 kg/m².

- You want to store goods on different levels depending on access frequency (low access products on the top level, high access products below or at ground level).

Do some of these points match your experience?

Read more or contact us directly on

(01) 5686718

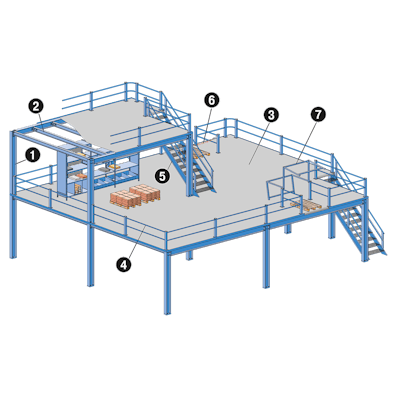

The BITO mezzanine system

The BITO mezzanine system is highly stable, flexible and available in a number of variants. This means it integrates well into many different warehouse designs.

The installation’s multi-tier design lets you design each tier to meet a different set of requirements, making effective use of cost-intensive storage space.

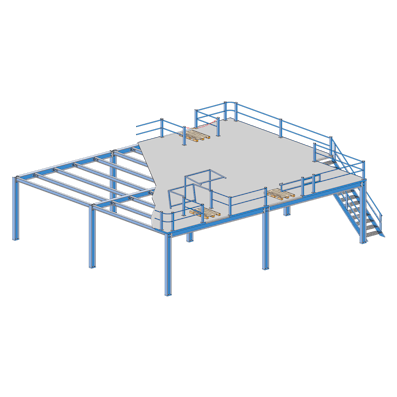

If you need to store heavy loads, you need to use a corresponding high-capacity, suitably designed shelving system. Thanks to an extremely stable self-supporting steel frame, the mezzanine system is ideally suited to storing heavy loads - for storing distributed loads up over 1,000 kg/m², given a suitably sturdy warehouse floor.

Columns and joists form a rigid base structure which does not require cross bracing, permitting access from all sides. Mezzanine platforms/tiers can be adjusted at any required height.

We work together with you to plan your mezzanine and adjust its construction and equipment to precisely meet your specific requirements.

Your benefits

Perfect space utilisation with compact storage on several tiers:

- High degree of floor space utilisation

» The BITO mezzanine system offers extensive storage space in the same surface area. Adding a mezzanine will multiply your building’s storage efficiency several times over.

- Space usage: increased by 100 per cent

» The BITO mezzanine system lets you truly make full use of your storage capacity, including vertical space. This lets you more efficiently and cost-effectively offset high building occupancy expenses, with space usage increased by up to 100 per cent.

- Open up additional space

» The mezzanine’s multi-tier design opens up additional storage, picking and/or assembly space. The area under the mezzanine can also be used to meet your needs - as a work area, for example.

- Faster order completion

» Effective use of vertical space with a multi-tier installation enables parallel picking across multiple tiers - with direct access to all items. This streamlines order processing.

Mezzanine construction

1. Columns

Columns for BITO mezzanines are manufactured from solid steel profiles in dimensions to suit intended load requirements.

2. Joists

Joists are manufactured from solid or slotted steel profiles in dimensions to suit intended load requirements.

3. Decking

Chipboard decking, galvanised mesh decks and chequer or teardrop plates are available as decking options. We’ll help you to find the ideal material to suit your individual requirements and the type of load carried.

4. Railing

The sides of BITO mezzanines meet professional association standards for safety requirements and all applicable European standards. The guard railing consists of solid, tubular hand and knee railing. The kickplates have been made from bended steel sheet which is fitted around the edges of platform levels and walkways to prevent small parts from falling down to the levels underneath. These provisions ensure that your employees can work safely even at high elevations.

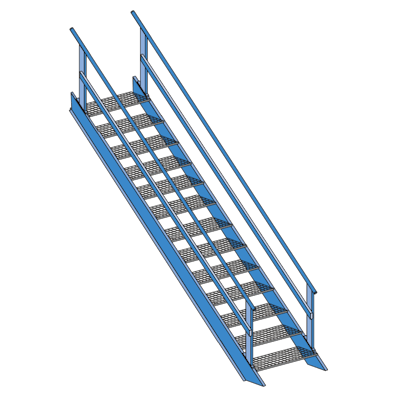

5. Stairways

The stairways to the mezzanines are equipped with safety barriers and can be optionally supplied with or without an intermediate landing. The steps can be safely climbed and are available in tread widths of 800, 1,000 or 1,200 mm. Depending on your needs and requirements, they can be made from galvanised mesh, chequer plates or wood.

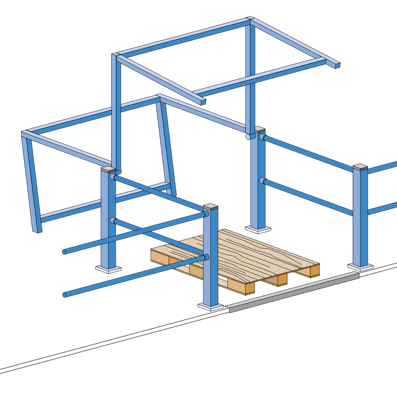

6. Set-back pallet transfer position

Pallet transfer positions can be set up on mezzanine floors or walkways, enabling safe and easy goods replenishment and material handover. Set-back pallet transfer positions with barrier chains are the most cost-effective variant. They consist of a hand and knee rail and two posts with a red and white plastic chain which can be unhooked as required. The chain is set back at least 800 mm.

7. Swing access gate

Swing access gates, the second variant of the pallet transfer position, always have one side closed depending on the direction of transfer. This ensures optimal personal safety during transfer, especially at high elevations. Particularly easy to use.