Ideal if...

- You need constant access to all products in your range.

- You need a versatile storage system and want to store a wide range of items in all kinds of shapes and sizes.

- You want to store large quantities of each item, with a relatively small range of goods. Naturally, you can also store a wide range of goods, each type in small quantities.

- You want to pick goods directly from the pallet and use the upper shelves as buffer space.

Do some of these points match your experience?

Read more or contact us directly on

(01) 5686718

The BITO pallet racking system

Classical pallet racking remains, as ever, the most popular storage system for palletised goods - despite the increasing use of modern technology in the storage and picking fields.

The system allows convenient access to every pallet. Moreover, the racking configuration can be easily modified and extended. Flexibility and relatively low investment costs have made this system essential for storage and order picking.

With useful and practice-proven accessories, the BITO pallet racking system allows optimal storage of palletised loads in all shapes and sizes.

The most common configuration is multi-position storage with 2 - 4 pallets per bay. If pallets are buffered or if complete pallet loads are to be handled, pallets are stored short side facing. For order picking, however, pallets are generally stored long side facing in order to facilitate access.

The pallet racking system is available in a range of versions, the most common of which are broad aisle racking, narrow aisle racking and mobile pallet racking.

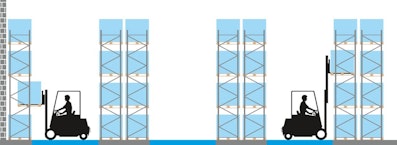

- Broad aisle racking

Broad aisle racking is the standard solution for pallet racking. In this design, servicing is generally done with front stackers, reach trucks or man-up stacker cranes. The aisle width is intended to suit fork lift truck dimensions. The floor level can be conveniently serviced with a hand pallet truck or an electric lift truck.

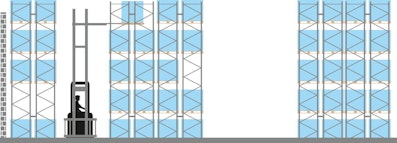

- Narrow aisle facility

This high-rise structure with narrow aisles enables ideal use of vertical capacity and efficient use of floor space. As a rule, narrow aisle facilities are serviced with man-operated stacker cranes or order picking trucks. This allows picking of smaller unit loads from all racking levels. Guide rails and inductive steering ensure that service vehicles always keep the ideal distance to the installation.

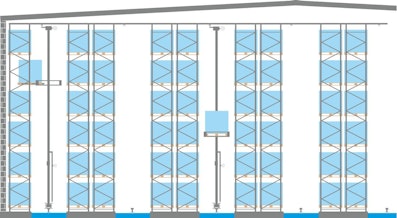

- Mobile pallet racking

The use of mobile pallet racking reduces the need for costly floor space. Thanks to the racks’ mobility, only one aisle needs to be open for picking at any one time; the rest of the space is filled as efficiently as possible with closely-packed racking runs. Each of the individual racking runs can be relocated, allowing access to all pallets at all times. Instead of one broad aisle wide enough for truck circulation, it is also possible to open several smaller aisles.

- Automated servicing

Alongside classical palletised storage and retrieval, automated picking and the use of shuttle carriers are growing in importance. The higher initial investment costs pay off quickly thanks to significantly faster picking and order processing.

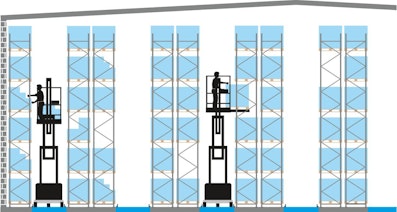

- Other designs

Multi-tier pallet racks allow multiple employees to pick goods at the same time to process significantly more orders.

BITO pallet racking also works perfectly with other racking systems such as live storage. It can be combined into a broader system, adjusting perfectly to the logistical processes in your warehouse.

Videos

Watch video on Pallet racking in

YouTube

BITO PRO pallet racking

Future-proof picking: Easily tuned racks let you design your picking side to be more ergonomic and flexible.

Warehouse safety is always in the spotlight for us! We offer a wide range of accessories to help, including our upright protector.

The BITO extractable first pallet position makes picking significantly faster and easier on employees’ backs.

Your benefits

General benefits:

- 100 percent access

» Unlike block or aisle-based storage, classical pallet racking allows complete access to all stored items. Each pallet can be easily accessed.

- High degree of flexibility

» The pallet rack can be easily reorganised and expanded. It is the most versatile, flexible heavy-duty storage system, permitting the storage of goods and packages in all shapes and sizes.

- Easy picking

» Pallet racks are compatible with all modern lift truck types and picking vehicles.

- Low investment costs

» Basic investment costs for a pallet racking system are low.

General benefits of each pallet rack type

- Broad aisle racking

» The entry-level variant for cost-effective pallet storage. Ideal for flexibly storing a wide range of goods while providing direct access to all items. Broad aisle racking is compatible with all modern fork lift trucks.

- Narrow aisle facility

» Ideal for optimal usage of existing floor area and vertical space. No need to transfer items to be picked down to a lower level - using man-up narrow-aisle lift trucks, you can pick goods from any shelf. The system offers high operating stability, as there is no need for individuals to wait in the aisles.

- Mobile pallet racking

» Highly effective: surface area is used as efficiently as possible; storage capacity is correspondingly high while huge amounts of floor space are saved. Particularly in cost-intensive deep-freeze storage, the compact structure reduces space requirements - and therefore energy costs - dramatically.

System-specific advantages:

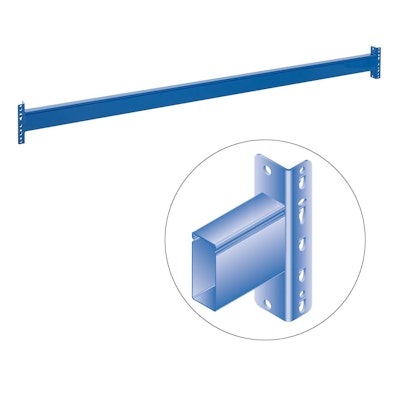

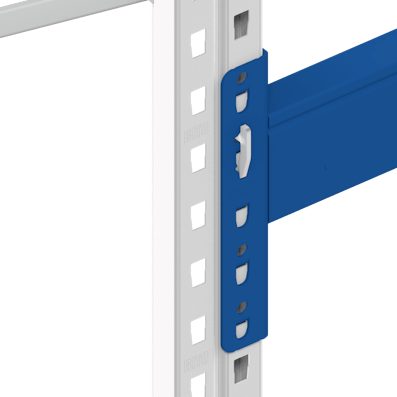

- Colour

Galvanised frames and plastic-coated blue beams stand out clearly against wooden pallets, allow colour-coded division and therefore ensure greater safety when storing and retrieving items - especially on high shelves. Colour combinations also make for a more pleasant working environment.

- A broad range of accessories

A wide range of accessories and safety equipment complements the pallet racks’ modular approach. They ensure smooth running in your warehouse, minimise damage to the racks and therefore help to prevent certain losses.

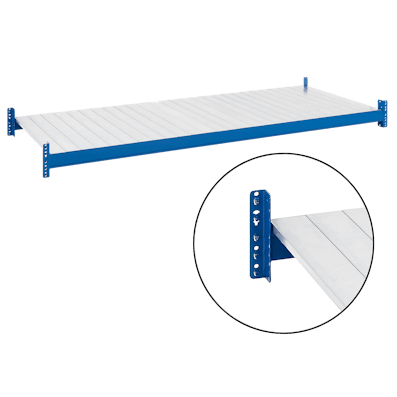

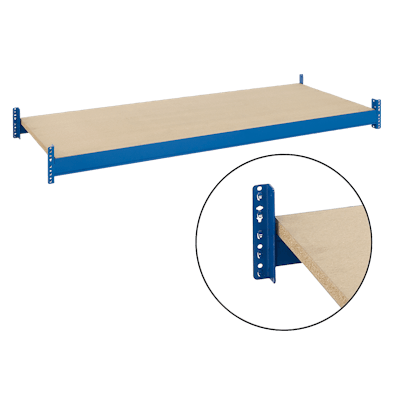

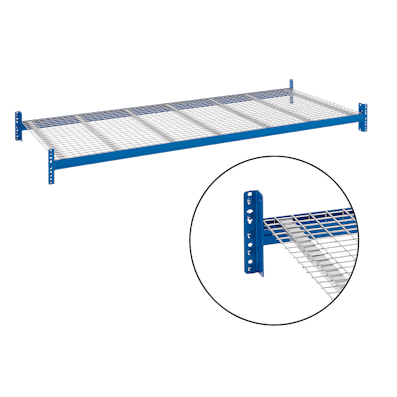

- More accessories for shelves

Depending on the load carriers or the goods to be stored, the racking system's shelves can be fitted with a wide range of different drop-in segments.

- Convert stock-keeping warehouses into picking zones

As a manufacturer of live storage systems, we can use pallet racks to turn your stock-keeping warehouse into an efficient picking site. Effortlessly and ergonomically pick boxes, containers and even individual components from the lower levels, while storing replenishing supplies on the upper levels.

- Quality certificate

BITO pallet racking carries the RAL quality mark, a particularly special distinction.

- Wide range of storage options

Pallet racks are suitable for both long side on and long side facing storage, as well as single- and multi-position storage.