Schwälbchen

BITO PROmobile maximises the use of limited storage space

Our customer

Since 1938, Schwälbchen is a recognised high-performance creamery running three sites – Mainz, Ilsfeld and Korntal-Münchingen. Whereas only 4 million litres of milk were processed annually in 1938, today's processing capacity has risen to almost 150 million litres a year. The "green" product range "Grüne Linie" provides fresh milk and products that have to be kept cool such as cream and cheese. The company employs 385 people and is known for supplying local products and catering size packs to gastronomy.

Initial situation and customer requirements

- Schwälbchen needed a storage capacity of 1,300 pallet positions (Euro pallets) for fresh produce.

- Full pallet loads are to be buffered.

- Optimal space utilisation to cut energy costs while guaranteeing a constant storage temperature of +5°C.

Project brief

The BITO Solution

Optimum space utilisation

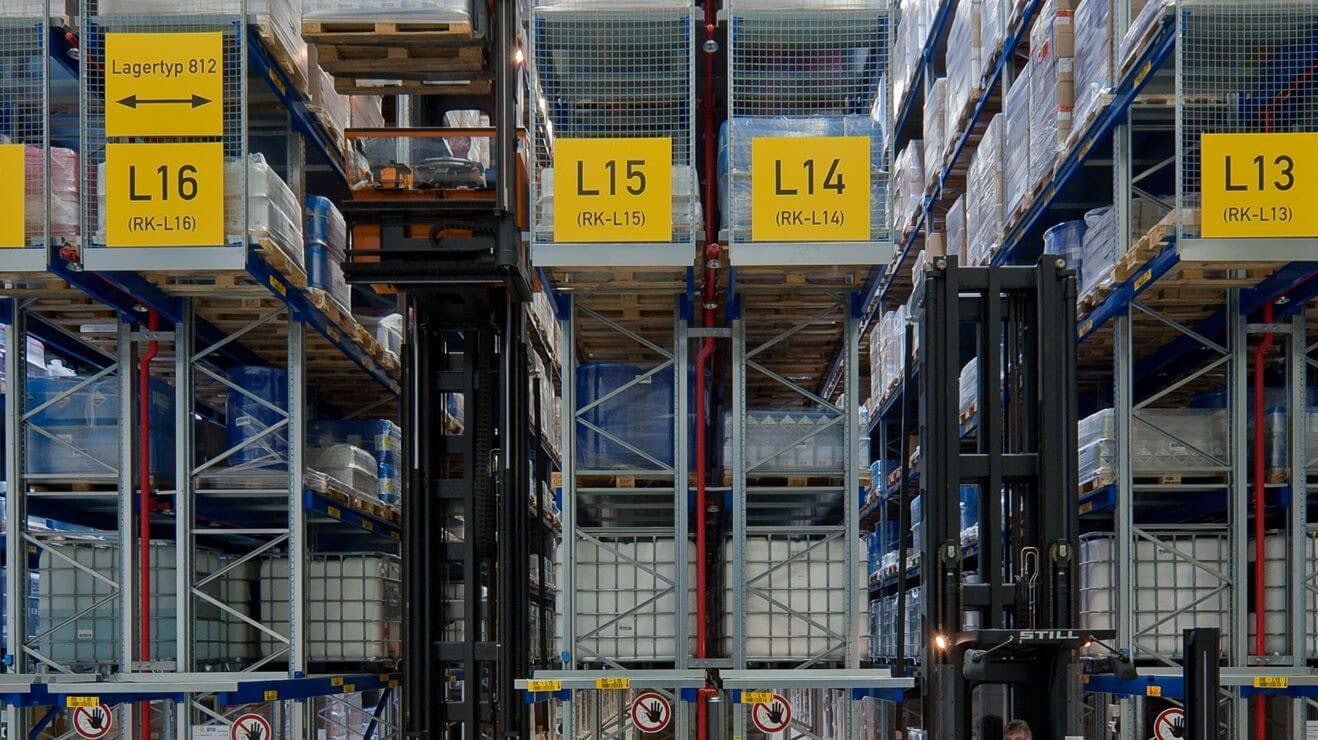

» Mobile pallet racking BITO PROmobile

Customer benefits

In what way has the BITO solution helped our customer to realise their full potential?

- 75% increase in storage capacity with BITO PROmobile pallet racking

- Space occupation has risen from 40% to 75%, since less service aisles and less service vehicles are needed in comparison to a static storage solution.