What are storage systems?

Types of storage solutions

Storage solutions comprise various elements for the storage and organisation of a company’s goods or equipment. A good solution will help to control the flow of materials and the associated information, as well as playing a key role in optimising storage capacity. This is why storage systems are regarded as one of the most important elements of intralogistics.

A range of options for a range of applications

An efficient and well thought through storage solution will lead to reduced transport and walking distances, as well as faster product access times. Further advantages include high handling performance, agility to respond to change and goods delivered in prime condition.

A storage system will span the intralogistics process – from identification, examination and storage of articles through to dispatch. Vital elements will include the control system, warehouse personnel, warehouse management and warehouse and conveyor technology. Whether a static or dynamic storage system is required will depend on the different requirements of the application.

From small parts to trays for conveyors

To maximise usage of space, companies usually move from storing their products on the floor to storing them on shelves. To facilitate this, there are many different types of shelving & racking systems, with options for different types of goods. The most appropriate system will mainly depend on the size and weight of the articles and how the users need to load, store and pick the items.

Lightweight or small parts such as components or fixings can be stored in small parts containers that sit neatly on worktops, trolleys or shelving.

Pallet racking - either static or with roller beds, is required for the storage of goods stacked on pallets, stillages or pallet boxes. Pallets are placed on beams with the aid of a forklift truck.

Shelving systems, often known as boltless shelving, are ideally suited for the use of small to medium-volume goods such as cartons, files, or containers. Very often, the addition of dividers creates more locations in a system and maximises the usage achieved from shelving.

There are also more specialised solutions such as tyre racking, wide-span racking and cantilever racking for the storage of long goods such as tubes, plates or rods.

Trays, used on conveyors to act as load carriers, can be loaded with many different parts, container sizes and packaging units. This system offers a degree of flexibility in the warehouse that should not be underestimated and can enable conveyors to transport even the smallest of items.

The aim of a storage solution is to optimise the flow of materials and to balance fluctuations between supply and demand by ensuring that stock is located where it needs to be. A multitude of warehouse systems exist to support the different areas of a company’s functions.

Assembly or production lines also need stock warehouses to ensure the efficient and smooth supply of parts for production. Buffer storage is often required for different assembly or production stations.

Spare parts warehouses enable fast and precise delivery of spare parts, while distribution warehouses are the interface between a company and the customer.

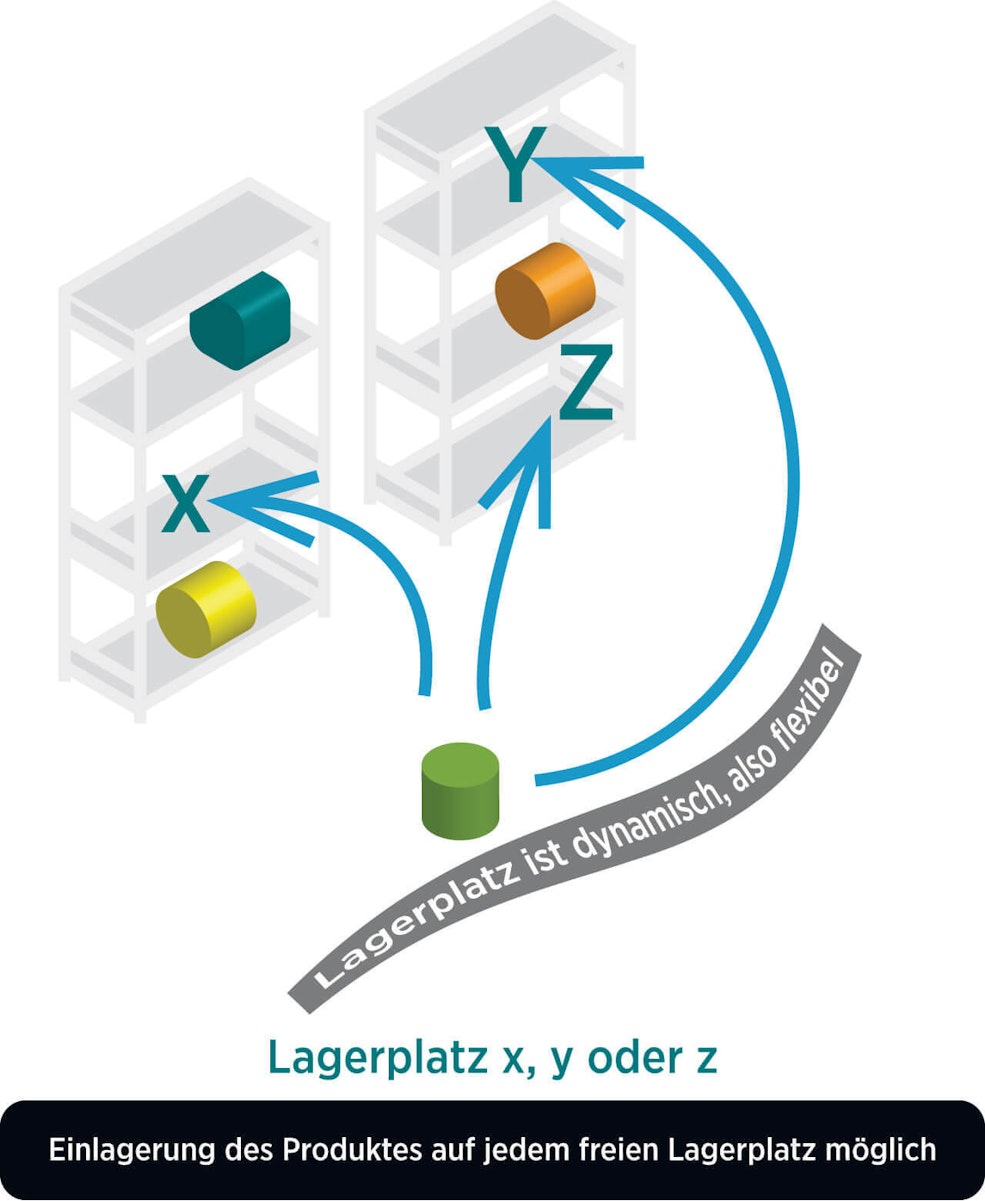

Static versus dynamic storage

In static warehouse storage, goods are stored and retrieved manually. Dynamic warehouse storage functions with the integrated use of automation.

If static storage techniques are used, the material is removed without automatic aids. The pallet or storage unit will remain in its locations during picking. This picking method is known as the person-to-goods principle.

Static storage systems are more commonly implemented and used across all industries because they offer great flexibility and scalability.

Dynamic storage systems move the unit during storage and retrieval, therefore bringing articles directly to the order picker with, for example, the aid of automatic conveyor technology. The picking method often used in dynamic warehouses, therefore, is goods-to-person picking. The dynamic, automated warehouse shortens the working process and saves space and energy. Dynamic systems are based on energy-efficient technologies as well as robust and durable designs.

Efficient and high-performance storage systems for all industries

Today, functional and intelligent storage systems with perfectly coordinated storage technology are an indispensable prerequisite for the success and profitability of companies in retail, manufacturing or general logistics. At BITO, we adapt our storage solutions to the wishes and needs of our customers. Our range of services as a provider in the field of storage systems and techniques includes advice and concept development, professional design and manufacture as well as professional assembly and commissioning. Our efforts result in efficient and high-performance storage systems for companies in all industries.