Digitization in intralogistics

Industry 4.0 and the increasing digitalization in industry are buzzwords on everyone's lips. As a new standard, Industry 4.0 pursues the increasing optimization of processes and workflows and thus the saving of time and costs. This is achieved through intelligent and digitally networked systems. People, machines, plants, logistics and products communicate and cooperate directly with each other in industry 4.0. The aim is to optimize entire value chains (supply chains) of products and their logistics. In the course of industry 4.0, there is also talk of a fourth industrial revolution.

Logistics 4.0 and intralogistics 4.0

Logistics 4.0 describes the effects of industry 4.0 on logistics. According to the Gabler Wirtschaftslexikon, "Logistics 4.0 is the networking and interlocking of processes, objects, supply chain partners and customers through information and communication technologies with decentralized decision-making structures in order to increase efficiency and effectiveness". The basis of digital logistics are processes and objects that can control and organize themselves and are therefore called "smart" or "intelligent". In this context one also speaks of smart logistics. GPS, RFID, cloud-based computer architectures, Electronic Data Interchange (EDI), Big Data, telematics and many more. A functioning intralogistics system is the key to efficient production within the framework of Industry 4.0. For this reason, the logistics processes in companies in all sectors must of course be digitized and optimized accordingly. Above all, companies that operate on international markets and have a large customer base must digitize their intralogistics systems in such a way that their sales are not jeopardized. In the factory buildings of the future (keyword: Smart Factory) all objects will be intelligent: the material, the containers and the transport systems. They know their own identity and abilities and can network with each other. Workpieces are then equipped with control and communication technology and automatically roll to the individual stations, where they can use RFID to place their own orders for further assembly. The transport of goods can then be carried out by automated guided vehicle systems (AGVs).

Automotive industry leads the way in digitization

The automotive industry in particular already has advanced intralogistics and is once again fulfilling its role as a pioneer in industry and logistics. Drones and intelligent AGVs are already part of everyday life in many warehouses, minimizing hectic and chaos and making entire companies more efficient. Transport and logistics in particular is one of the core topics in this context, which harbours a massive potential for digitization, since transport routes in a classic warehouse cause the most waste of space. Not only do they have to meet special requirements in terms of safety and escape routes, but they also have to be wide enough so that the transport vehicles used in the warehouse have sufficient space for loading, driving and manoeuvring. This is absolutely necessary on the one hand, but on the other hand these things take up a large part of the storage space, which could also be used more efficiently. Thus they are the first starting point to carry out a digital transformation.

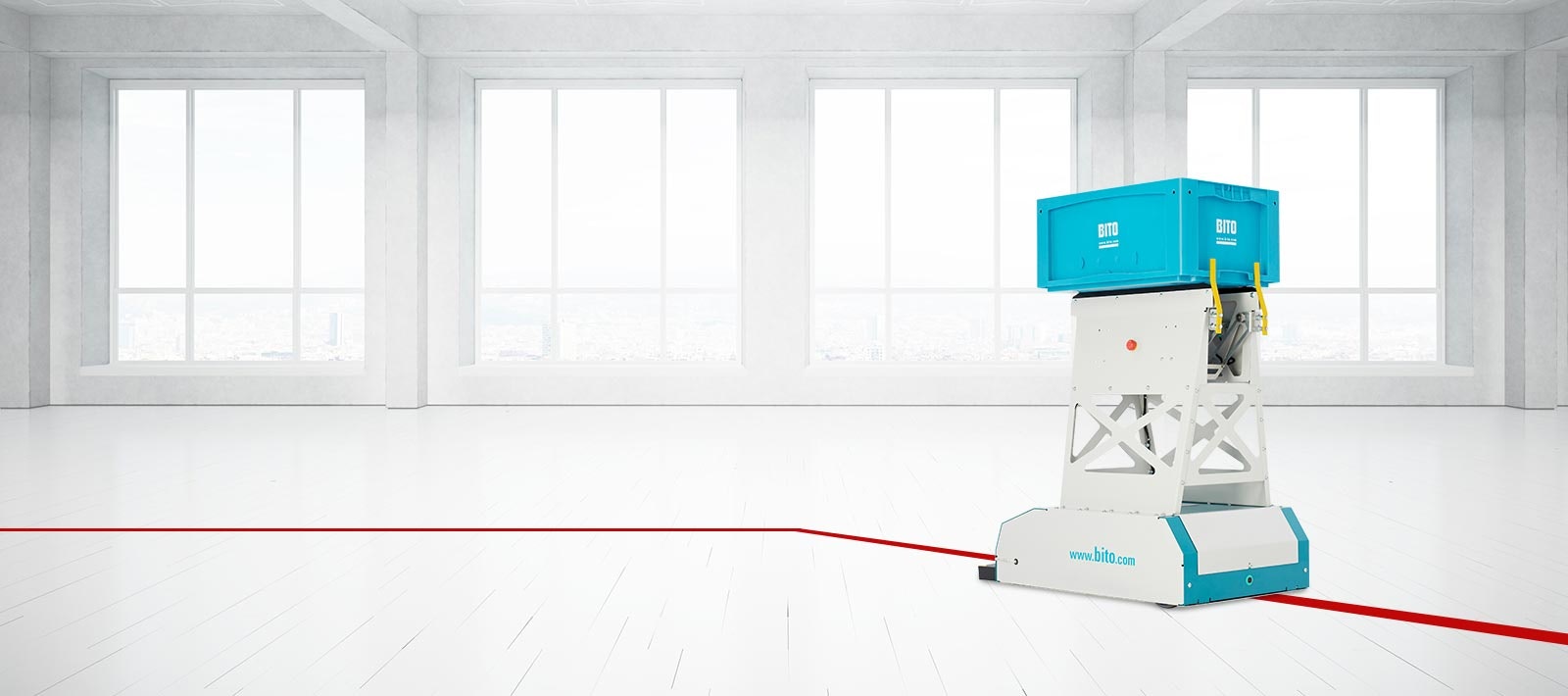

FTS are an important component of intralogistics 4.0

FTS offer the best prerequisites for converting a company's intralogistics for a digital future. With FTS, the number of empty and wrong runs can be massively reduced because the vehicles automatically drive to the right shelf. They are based on various technologies such as indication strips, precision lasers, reflectors or simple traces of adhesive tape. While most intralogistics warehouses today still rely on industrial trucks such as forklifts, whose drivers drive on sight and call, AGVs follow an automatically programmed path. For this purpose, a visual trace can be used, for example, which an FTS can follow on its way. Bottlenecks, collisions or other hindrances in the workflow can thus be almost completely eliminated. This makes the intralogistics of a company faster and more efficient. The challenge lies solely in creating an open infrastructure.

Bearing guidance systems form the backbone

Modern Supply Chain Execution Systems (SES) such as the Warehouse Management System (LFS) control, monitor and optimize networked logistics in the age of digitalization. For example, the LFS has all the necessary interfaces to communicate with all devices and higher-level systems. The collected data is used to optimize the entire value chain. SES are therefore the backbone of Industry 4.0 and Logistics 4.0.

Blockchain technology for logistics

Today, data is often stored in cloud solutions and networked with each other. One problem is the validation of the data. Are they from the source they claim to come from and are they still in their original state or possibly manipulated? But the Internet, via which machines, systems, devices, etc. can communicate independently, also requires standardized interfaces. The data exchange or communication is secured by blockchains. This is because data and possible changes are stored unambiguously and unchangeably in the data record of the blockchain when they are passed on by cryptography. Blockchains can also run Smart Contracts, such as the billing of a transport, fully automatically.

Integration of all employees in the transition to industry 4.0

It is also clear that digitization in intralogistics brings a number of opportunities. Despite all the major technical advances, it is essential not to forget the human workforce in intralogistics, as the integration of employees into new, digital processes is extremely important. Only if a company really gets everyone involved in a company on board - can the digitization of logistics and the entire company be successfully implemented. The main focus here is on eliminating fears and reservations, such as job loss due to new technologies, passing on technical know-how and convincing the entire team of digital strategies. Digital goals can only be achieved if everyone pulls in the same direction and drives forward the digitization of intralogistics in the same way.

Fascinating combination of man and machine

Automation, Industry 4.0 and Logistics 4.0 have long since arrived in all sectors. Driverless transport control systems (AGVs), drones and robots relieve many warehouse employees of everyday work processes. In addition to robots, FTSs in particular are proving to be innovative logistics solutions that have the best prerequisites for converting a company's intralogistics to a digital future. The fascinating connection between man and machine is increasingly taking shape.