Standardise your warehousing processes and stock management by applying best practices

The BITO WMS handles both inventory management and process control (order monitoring) in your warehouse based on best practice guidelines. The BITO WMS can be used both as a stand-alone system and integrated via interfaces in higher-level host systems, e.g. in an ERP or a merchandise management system or an online shop system.

The core functions include:

- Mapping of warehouse structures (zones, shelving and racking, storage positions, etc.)

- Master data management (customers, articles, storage positions etc.)

- Inventory management

- Order management (purchase orders, sales orders, production orders)

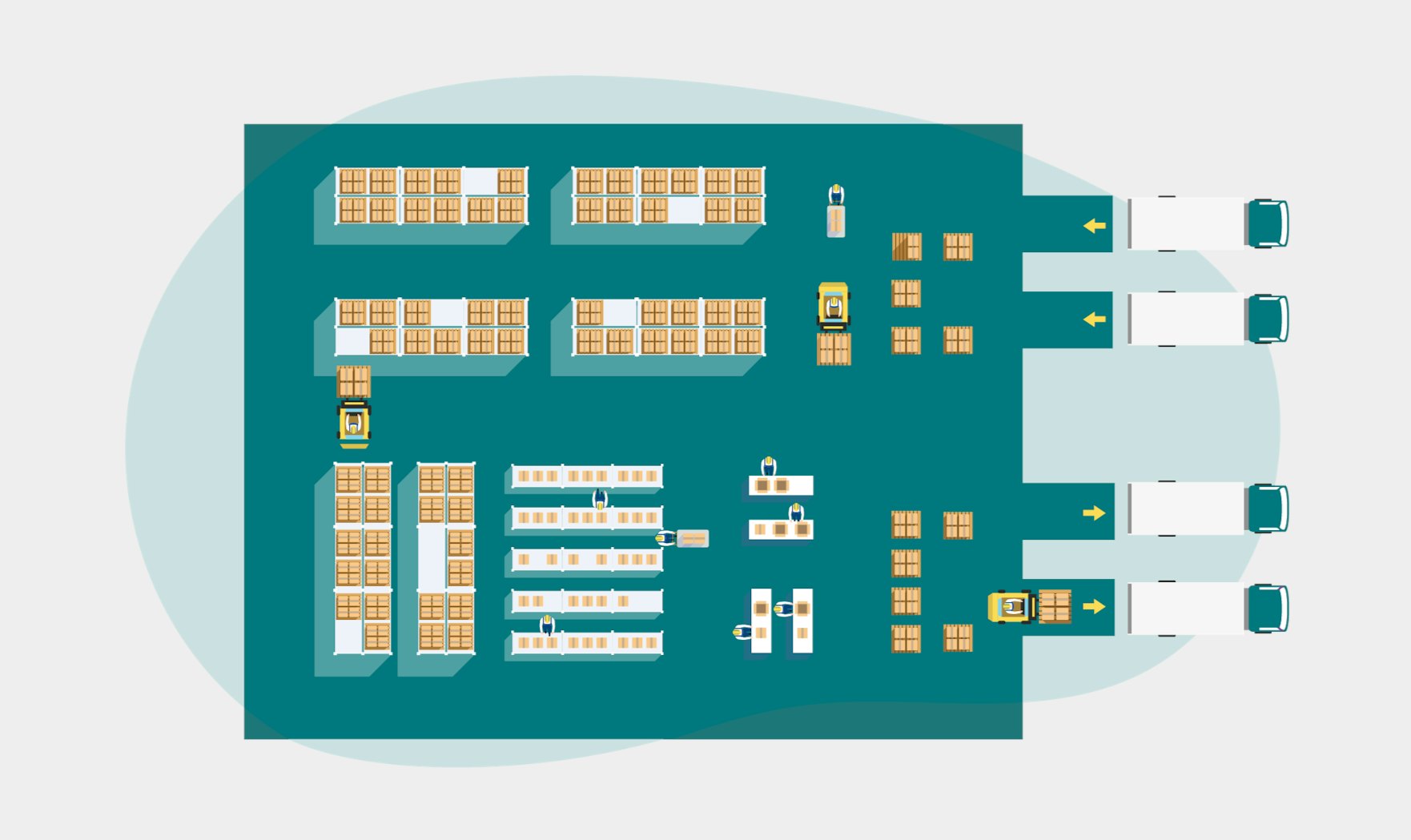

- Transport management (forklift transport routes, storage, retrieval and relocation of goods)

- Key figure system/KPI (for monitoring order processing, capacity utilisation, productivity etc.)

- Process handling:

- Goods receipt (order notification, entry into booking system, quality inspection, moving goods to storage position)

- Goods dispatch (order scheduling, order picking, packing, shipping)

Additional features

for further optimising your warehouse management processes and increasing efficiency

- Returns management

- Cross docking

- Handling of hazardous substances

- Load carrier management

- Third-party logistics (3PL)

The BITO WMS maps workflows, taking different storage strategies into account. Based on the storage system used for order picking, the BITO WMS takes various aspects into account such as pick&pack processes, multi-order picking, various route optimisation strategies and ergonomic aspects.

The system is able to distinguish between operational processes such as such as product loading, retrieval and relocation that are controlled with a mobile end device (Android or web app) and PC-controlled processes using a web app). This category includes f. ex. administrative processes such as entering orders and evaluating key figures.

Why should you opt for a BITO WMS?

Optimise your logistics processes

- Best Practice standards

- Improved transparency

- Accurate stock control

- Reduced process costs, in particular:

- Less picking errors

- Fewer returns

- Shorter order throughput times

- Digital data exchange through standard interfaces

- and other benefits

- Fully digitised process handling with mobile devices

- Little training required

- Low investment and running costs

- Contracts can be terminated on a monthly basis

- Cloud-based carefree package

Synergy between storage equipment and warehouse software

The rapidly growing furniture manufacturer METALLBUDE benefits from optimised warehouse processes

What our customers say:

“With BITO shelving and pallet racking as well as the PULPO inventory management system we were able to significantly improve our logistics processes.”

Our solutions in detail

PULPO WMS

The Pulpo WMS is a lean solution for e-commerce businesses

Web and app-based (SaaS)

Plug & Play implementation within 6 weeks

Ready for use in 3 steps:

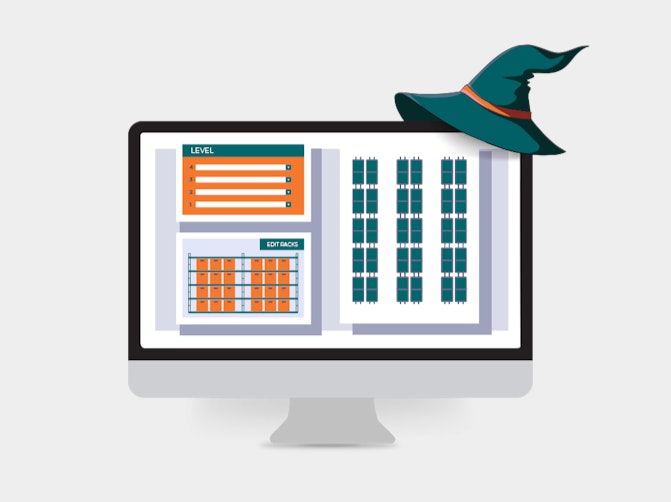

- Design your warehouse using the Warehouse Wizard

- Connect your shop or ERP system (plentymarkets, Shopify, Odoo, Bilbee, Xentral, Woo-Commerce, Magento) via REST-API

- Create your master data (customers, articles etc.)

... and get started!

Pulpo has been designed for intuitive use and is able to handle

goods-in, storage, picking, packing and shipping processes, stock level monitoring and returns processing.

COGLAS WEB WMS

The allrounder for distribution and production logistics

Web-based solution (as SaaS or On-Premise solution)

Rapid implementation within only 8 weeks

Can be integrated into existing ERP systems (f. ex. SAP, Navision, SAGE etc.)

Configurable to all standardised logistics processes such as

goods-in, storage, order picking, shipping, inventory monitoring, etc.

There are many additional features available such as

- Load carrier management

- Production management

- Hazardous goods handling

- Tugger train applications

- Transport order handling