Facts & Challenges

The Food & Beverage industry is about manufacturing, processing, distributing and selling food and beverages for human consumption. The food and beverage industry is made up of a wide range of businesses, including restaurants, cafés, bars, hotels, catering service providers, food manufacturers and distributors, and beverage manufacturers and distributors. They are active in both retail and wholesale and offer a wide range of culinary products and services. Well-known players in the industry include Nestlé, Unilever, Coca-Cola, PepsiCo, Danone and Kraft Heinz. The total turnover of the German food and beverage industry is around 200 billion euros. The industry employs around 1.2 million people. The food and beverage industry is heavily dependent on international trade. Germany exports food and beverages worth around 70 billion euros worldwide. Imports amount to around 100 billion euros.

<p<p>Social, economic and new technological trends are leading to a major transformation and in some cases are having a disruptive impact on the food and beverage industry. The increasing use of artificial intelligence (AI), automation, robotics, the Internet of Things (IoT) and blockchain technology are massively changing processes, business models and the interaction between players. One example is the use of blockchain technology to ensure the transparency and traceability of products in the supply chain. Consumers can thereby obtain trustworthy information about the origin and quality of the food. Companies can also organise food recalls more efficiently.

Social trends include sustainable and environmentally friendly practices, increasing health awareness, the individualisation and personalisation of products, practical and time-saving food and drink options, authenticity and transparency, as well as ethics and social responsibility.

Trends in food retailing

The food and beverage industry is facing various challenges such as increasingly strict regulations and standards, rising raw material costs, changes in consumer behaviour and sustainability requirements.

Change in consumer demand:

Healthy and nutritious foods, vegan and vegetarian products, convenience food and frozen products as well as sustainable and ethical products without meat are in growing demand. There is also a trend towards individualisation and personalisation of products in the food and beverage industry.

Consumers increasingly want to know where their food comes from and how it is produced. Transparency in the supply chain and authentic product histories are gaining in importance and are partly provided by blockchain technology.

E-food and online retail:

Large supermarket chains and retailers have recognised the e-food trend, which has also been strongly boosted by the coronavirus pandemic. They now have their own online shop and delivery service. There are also specialised e-food platforms such as Lieferando, Bringmeister and HelloFresh, which focus exclusively on online grocery shopping. Major market growth is expected in the e-food sector over the next few years.

Digitisation and automation are making inroads everywhere in the food and beverage industry – whether in production, logistics or sales. Industry 4.0 technologies (Smart Food Factory) are increasingly being used for flexible, safe and sustainable food production.

Use of AI:

Predictive maintenance of machines and systems, AI-based intelligent process control and quality monitoring, route optimisation during delivery and personalised nutritional recommendations are just a few examples of how AI is being used in the food and beverage industry.

3D food printing:

This technology can be used to make shape and texture modifications to foods. 3D food printing can transform the food sector by providing individualised meals, f. ex. through controlling the nutrient content.

The logistics sector has to cope with many requirements:

The rapidly growing online trade in the food and beverage industry in particular is placing high demands on company logistics: Examples include extremely fast and punctual delivery, efficient route planning, cold storage, maintaining the cold chain with refrigerated vehicles and cool boxes, freshness-preserving and sustainable packaging, separation of different product categories in the warehouse, storage systems for extremely fast order picking, traceability and quality assurance.

What are the requirements for logistics?

In the food and beverage industry, online retailing is speeding up the already complex logistical processes of companies. Many items in the food industry are frozen, chilled or fresh products that require appropriately refrigerated warehouses, transport vehicles and delivery boxes. In order to maintain the quality of the food, the cold chain must not be interrupted, which can be verified using blockchain technology, for example. Different cold zones must also be set up in the warehouse and certain products such as meat and vegetables must be stored separately. The entire logistics system must be flexible and able to adapt to seasonal demand and special offers with fast sell-offs. Companies in the food industry handle a large number of fast-moving items which are stored for example in carton and pallet live storage racking. They ensure storage in FIFO order and make sure that the best-before date is always adhered to. The food and beverage industry also uses automated storage systems such as shuttle-serviced pallet racking, Autostore and Microstore systems as well as pallet racking serviced with storage and retrieval machines (SRMs). Automated guided vehicles (AGVs), picking robots, cobots and other automation systems are also playing an increasingly important role. In general, a food warehouse must be very carefully planned, as many requirements must be taken into account such as large product portfolios, fluctuating demand, different temperature requirements, maximum shelf life, prohibitions on co-storage, compliance with cold chain requirements and fast and accurate delivery.

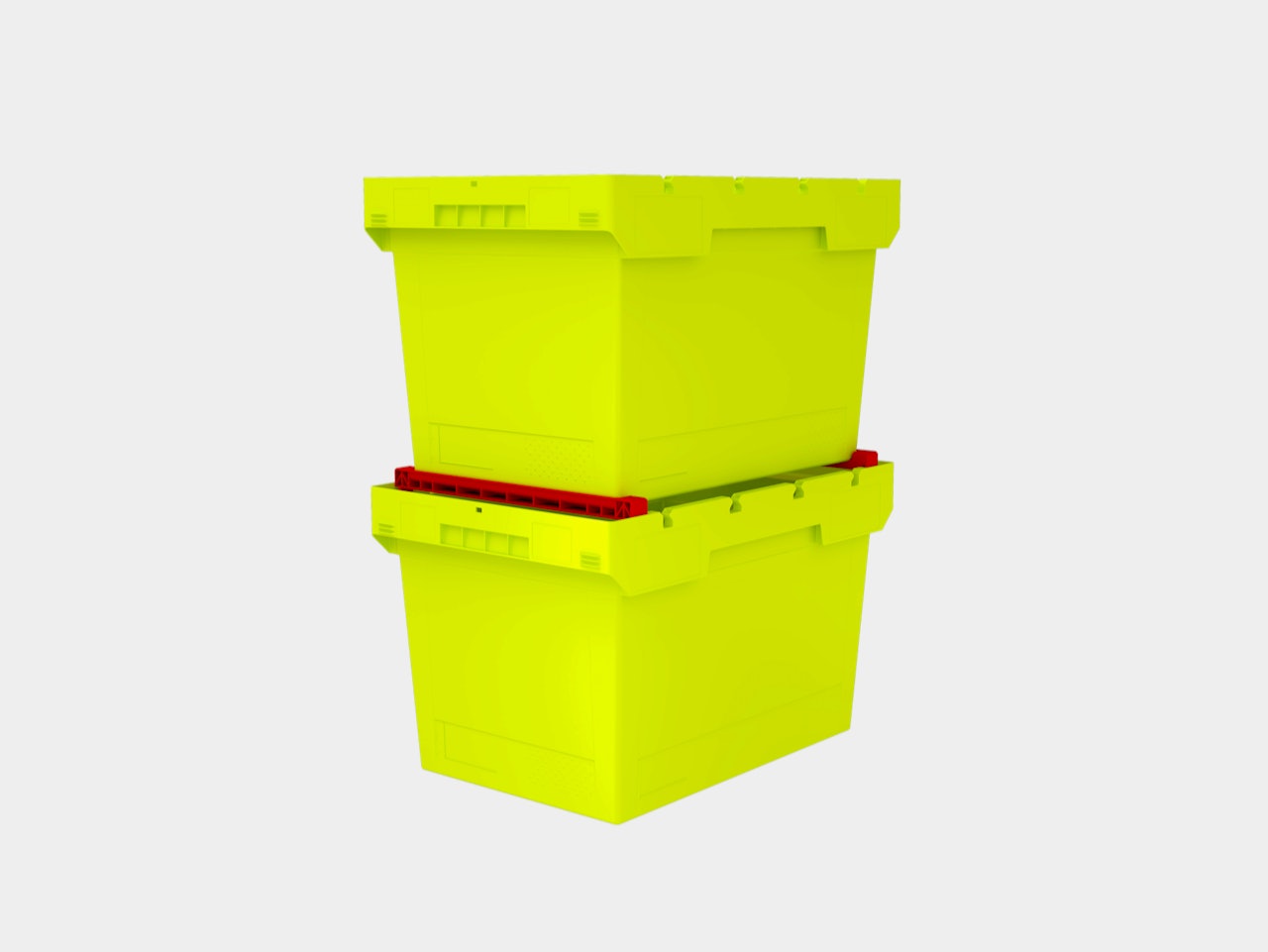

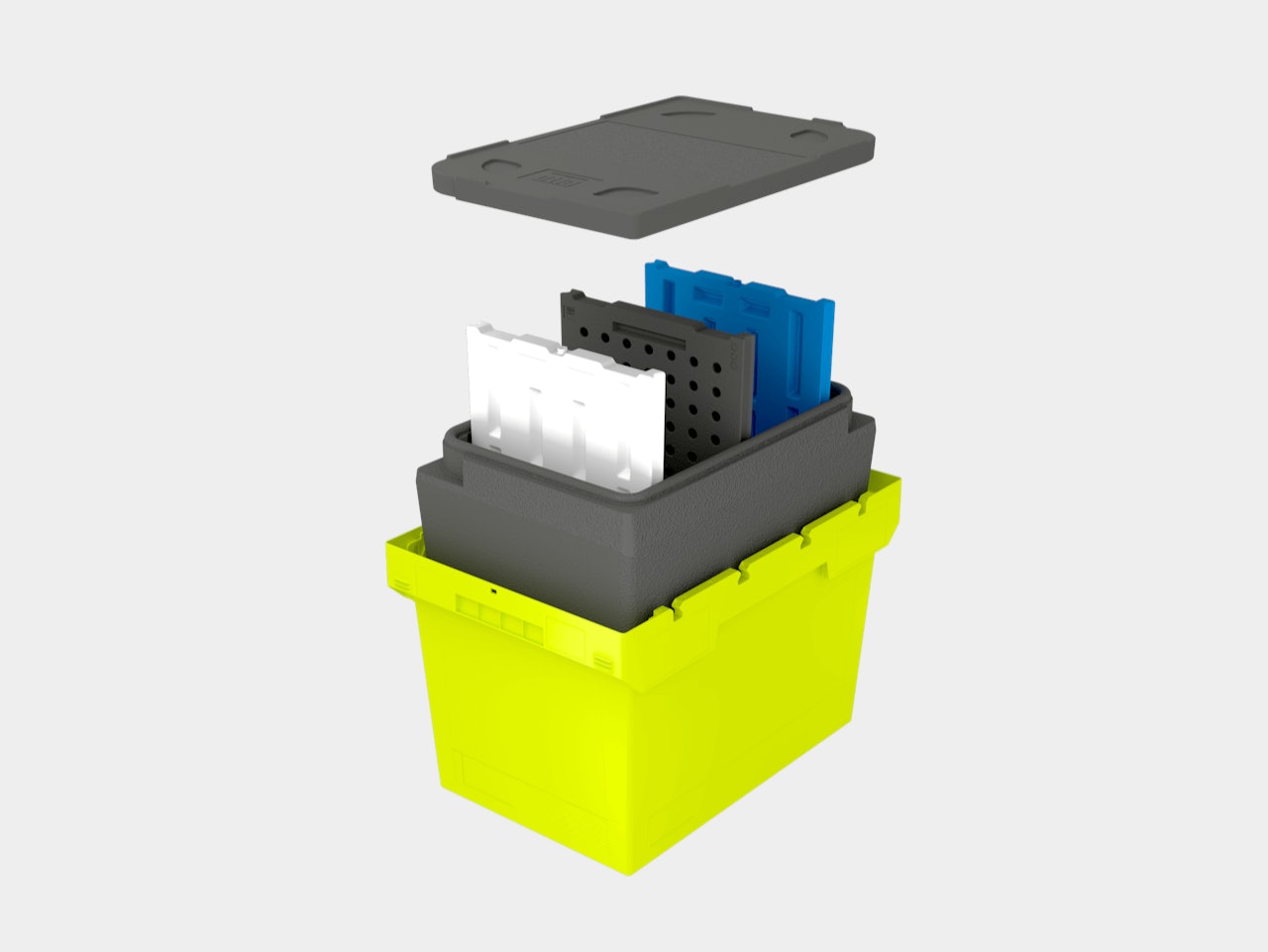

The MB Food & Delivery container series from BITO includes many container variants, modular insulating inserts, cold packs and dividers. They provide space-saving transport for many kinds of food. The containers are available in many different configurations. For example, various insulating inserts made of expandable polypropylene (EPP) can be used in the food industry in dry storage or refrigerated areas. The inserts are available in different sizes to create two different temperatures zones within the same MB container. Full height or half height cold packs help to maintain the right temperature. The MB Food & Delivery box is also available with ventilated sides ensuring optimal cooling is also achieved in refrigerated delivery vehicles and warehouses. Containers with vented sides weigh less, reducing the workload for employees. Separating inserts ensure that nothing can slip, tip over or leak. Empty containers can be nested to save space.

Optimise your food supply chain with our made-to-measure solutions

Flexible solutions for the entire supply chain

- Responsiveness to seasonal fluctuations

- Temperature control

- Compliance with the best-before date