What did Febelco need?

Dirk Claessens, Head of Technical Services at Febelco, explains: “In the past, we bought our racks through an integrator. Due to expansion plans, we had to revise the rack design so that we could go into more detail. In practice, we encountered shortcomings. We wanted to improve ergonomics and increase storage density.”

How did we solve it?

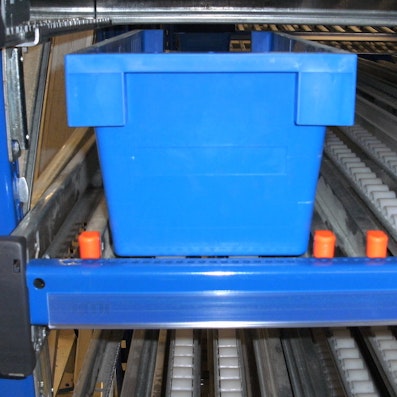

- With shelving and flow racks for general cargo. In total, this involves more than one kilometer of flow racks, in rows of 46 meters long.

- By clever use of the standard options of the system, the storage density increased significantly.

- This is because both cylindrical and flanged wheels are used. Dirk Claessens of Febelco explains: “When they arrive, most medicines are put in plastic containers after checking. We leave another part in the cardboard boxes. After expert testing by BITO, their advice showed that the cylindrical wheels were ideally suited for our boxes. And with flanged wheels for the plastic containers, we realized many more channels per flow level.”

The benefits for Febelco

- The items are easier to grab. That means time savings on orders.

- Thanks to the new, sophisticated arrangement, we can apply an extra flow level in height.

- Application of flow racks for general cargo reduces walking distances and increases picking efficiency. Febelco also gained about 60 percent space in the warehouse.

The customer testifies

“Both speed and productivity have greatly improved. The time between an order and the eventual expedition of medicines at Febelco is currently about fifteen minutes.

The flow racks for general cargo also enable FIFO. That in turn simplifies the monitoring of shelf life”.

Dirk Claessens, Head of Technical Service