Electrolux

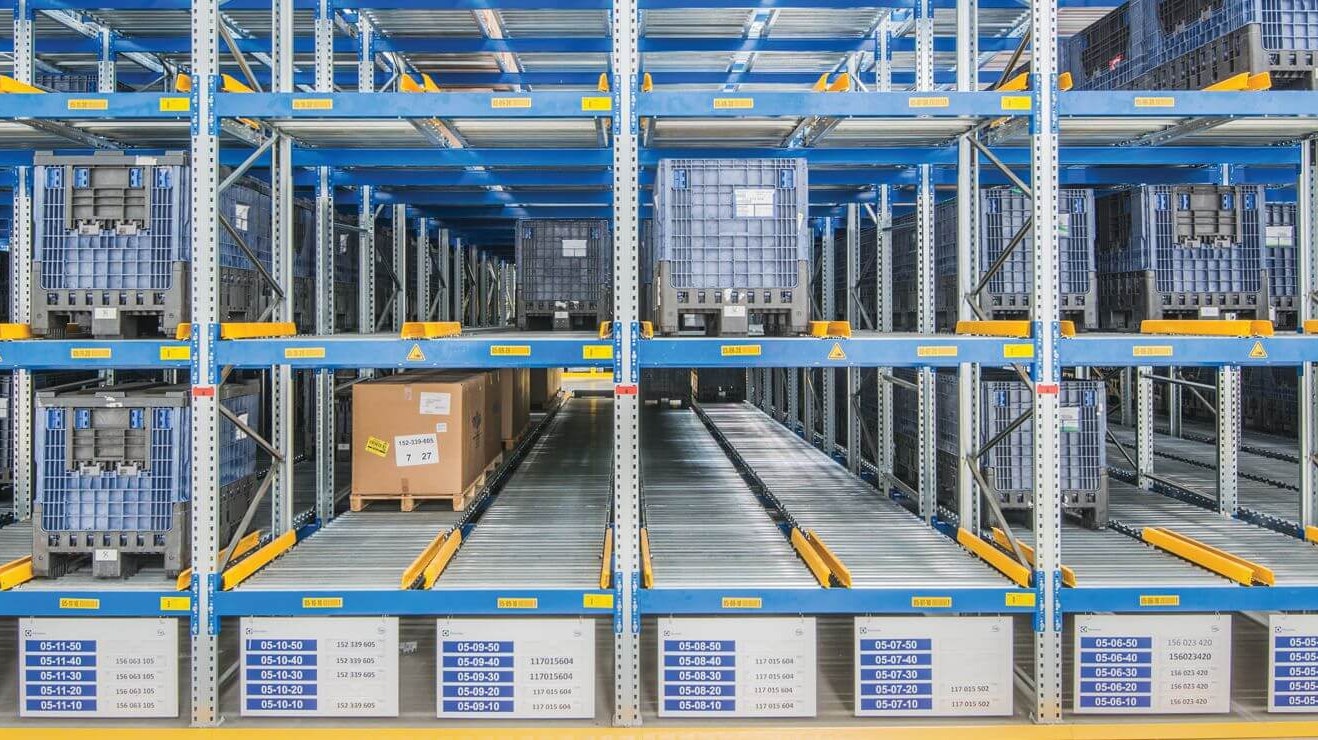

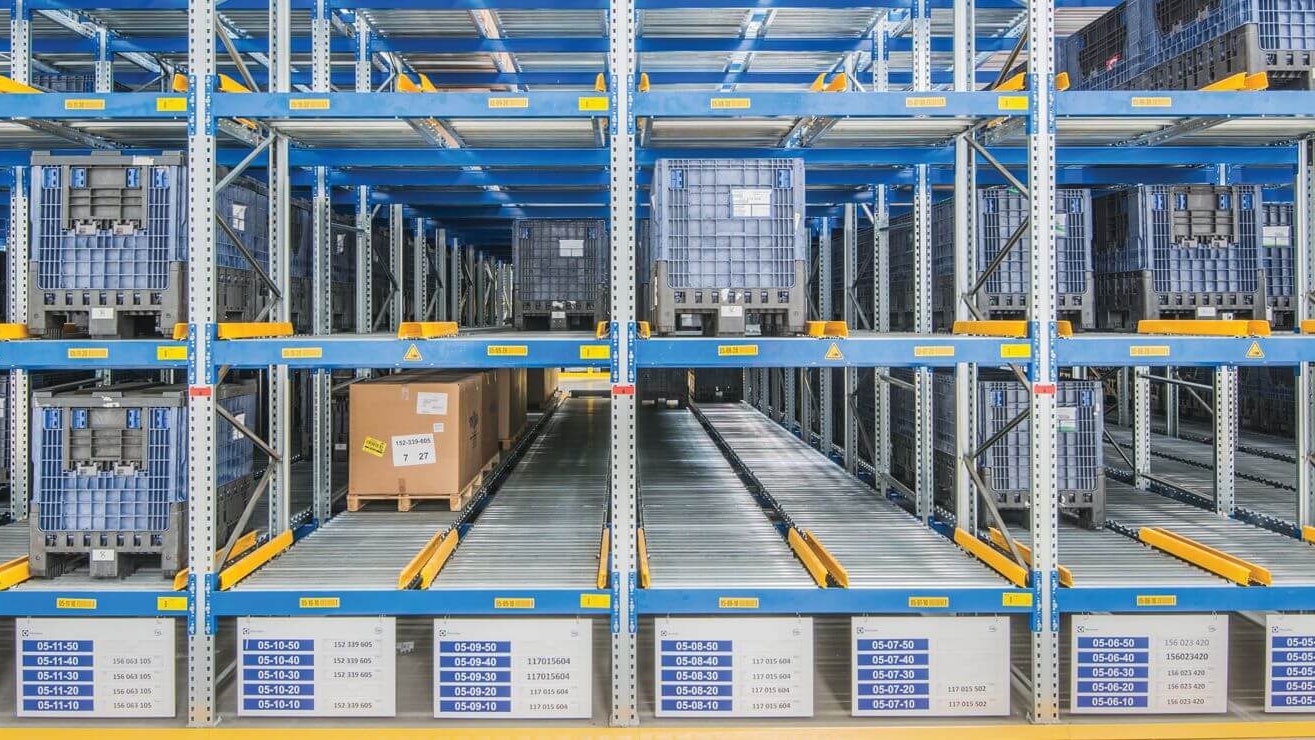

BITO PROflow ensures continuous FIFO product supply in the manufacturing process of a multinational home appliances company

Our customer

Electrolux is one of the world's leading manufacturers of household and kitchen appliances. Established in 1919 in Sweden, the group provides thoughtfully designed innovations. In 1925, the company started its activities on the German market and currently has a staff of 2,000 in Germany, with 1,300 employees working in the plant at Rothenburg ob der Tauber.

Initial situation and customer requirements

- The pallet racking installation is to provide 16 reference lines (B-line items) for order picking.

- Compliance with the FIFO principle must be ensured throughout the entire manufacturing process.

- Make best use of floor space and optimise in-house travel routes.

Some impressions of our customer solution

Project brief

The BITO Solution

FIFO product storage

» BITO installed PROflow pallet live storage racking to supply goods on a first-in, first-out basis.

On-site application and key features of our storage solution

- All 16 reference lines are stored in approximately 60 pallet boxes per reference line.

- The pallet boxes are picked up and delivered along the assembly line in a milk run cycle.

Customer benefits

In what way has the BITO solution helped our customer to realise their full potential?

- Space requirements can be reduced thanks to the small footprint

- Safety First: High level of safety when operating shelving and racking, very low risk of accidents

- Travel routes are shorter and transport costs are lower

- Safe process flow – no downtime on the assembly line