Electraline 3pMark S.p.A.

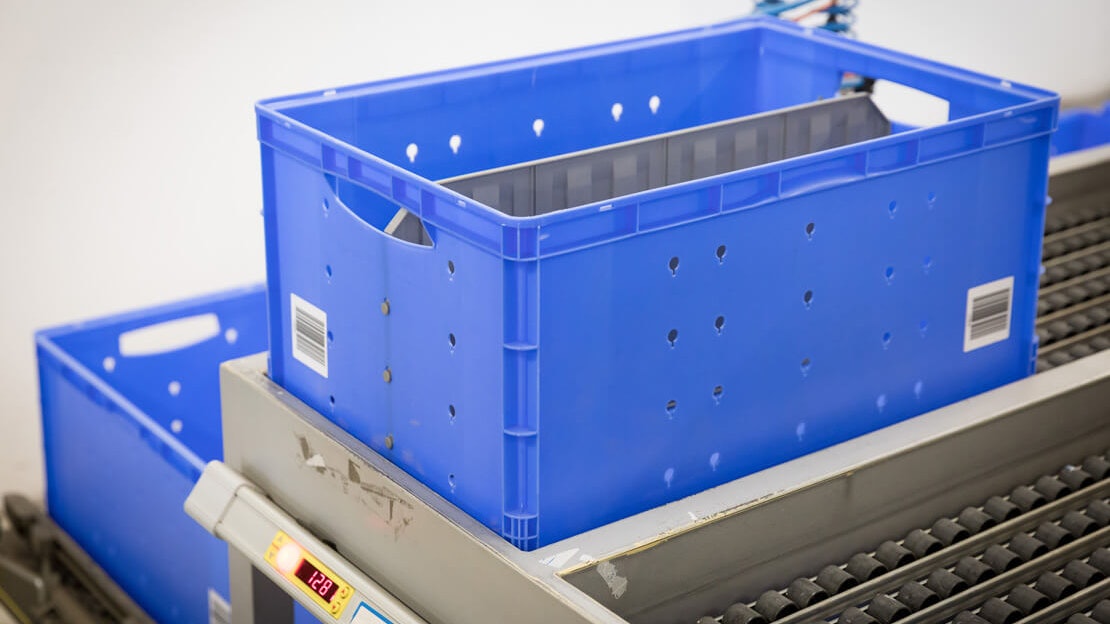

BITO XLmotion containers for flexible and efficient storage

Our customer

The Electraline Group is an international leader in the production and marketing of electrical equipment for the large-scale retail trade of DIY and food. The group was born in the late 90s with the acquisition of other companies that had been operating in the same production and sales area for many years. The Electraline Group has made the experience of its subsidiaries its own and over the years has operated with the aim of specializing the production units as much as possible, trying to maintain the flexibility necessary to provide excellent customer service.

In 2016, Electraline invested more than € 1 million in the construction of an automated warehouse to manage 2,100 out of a total of 3,300 references.

Some impressions of our customer solution

Project brief

The BITO Solution

7,800 XLmotion containers

Custom colour

Container base with drainage holes for use in warehouses with a sprinkler system

Allow containers to be subdivided into 2 up to 16 compartments. The dividers can be re-adjusted as required.

Application of barcode labels

Kundenanwendung und die Merkmale der Lagereinrichtung - hier müsste weiterer Text stehen

- Logistics area of 2,600 sqm on two levels

- Automated warehouse capacity 7,906 storage units

- 7,100 storage units in constant rotation

- 3,300 references in total; 2,100 references are managed in the automated warehouse

Customer benefits

In what way has the BITO solution helped our customer to realise their full potential?

- Internal subdivision into 2 to 16 compartments, adjustable to requirement

- Greater volume, compared to same size containers on the market

- Low-noise traveling on roller conveyors with an average of 63 dB (against the average of 67dB for other commercially available double base containers and 71 dB for containers with a reinforced base)

- Reduction of picking errors by up to 95%